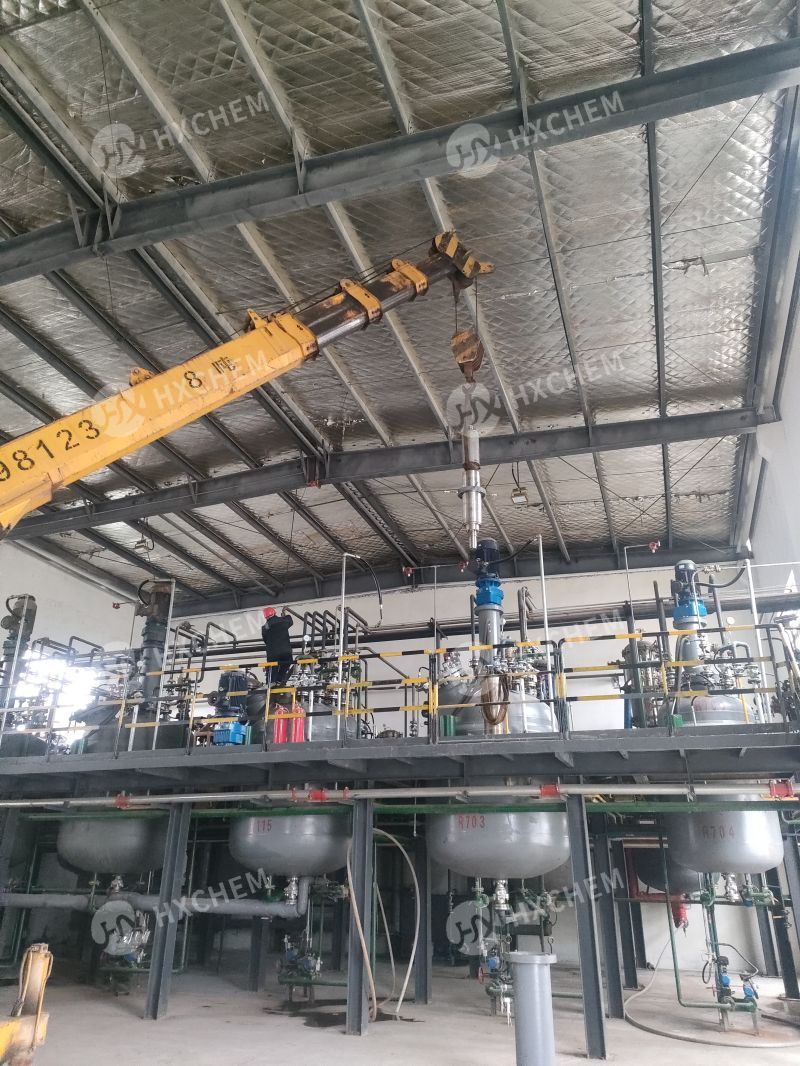

10kL hydrogenation autoclave

HXCHEM supply customized 10kL hydrogenation reactor; 10m3 hydrogenation reactor; 10000L hydrogenation reactors; hydrogenation autoclave; Industrial hydrogenation reactors.

- HXCHEM

- CHINA

- 70 days after payment

- 15sets/ month

Details

10kL hydrogenation autoclave/10000L Hydrogenation reactors

Introduction

Hydrogenation reaction is a liquid-gas-solid three phase reaction, HXCHEM SUPPY 10kL hydrogenation reactor, 10m3 hydrogenation reactors, 15kl hydrogenation reactors, etc. The stirring form of batch hydrogenation reactor is generally three-layer combined stirring, including paddle stirring, self-priming stirring and disc turbine dispersion stirring, which can also be selected according to user requirements. Our self-priming stirring paddle adds a set of riders, which can make the gas enter the hollow shaft of the stirring paddle more smoothly, and fully mix with the liquid gas.

Name: 10000L Catalytic hydrogenation reactors

Model: FCH-10000

Total volume: 10000litres;12000litres; 15000litres

Design pressure: 20bar.. up to 120bar;

Design temperature: Up to 300℃;

Jacket type: Oil/ Steam, Full jacket or limpet coil type;

Wetted material:SS304, SS316, hastelloy C22, hastelloy C276 solid or cladding;

Shaft seal: Mechanical or magnetic seal optional;

Certificate: GB; ASME U stamp; ISO certified; PED;

KEY FEATURES

Closed type with manhole

Vessel with jacket or half pipe coils

High hydrogen hold up & gas-liquid interfacial area;

Recirculation of the hydrogen;

Uniform suspention of solid catalyst;

No leakage magnetic coupling drive agitator

Internall cooling/heating coils, dip tube, baffles.

Safety valve optional.

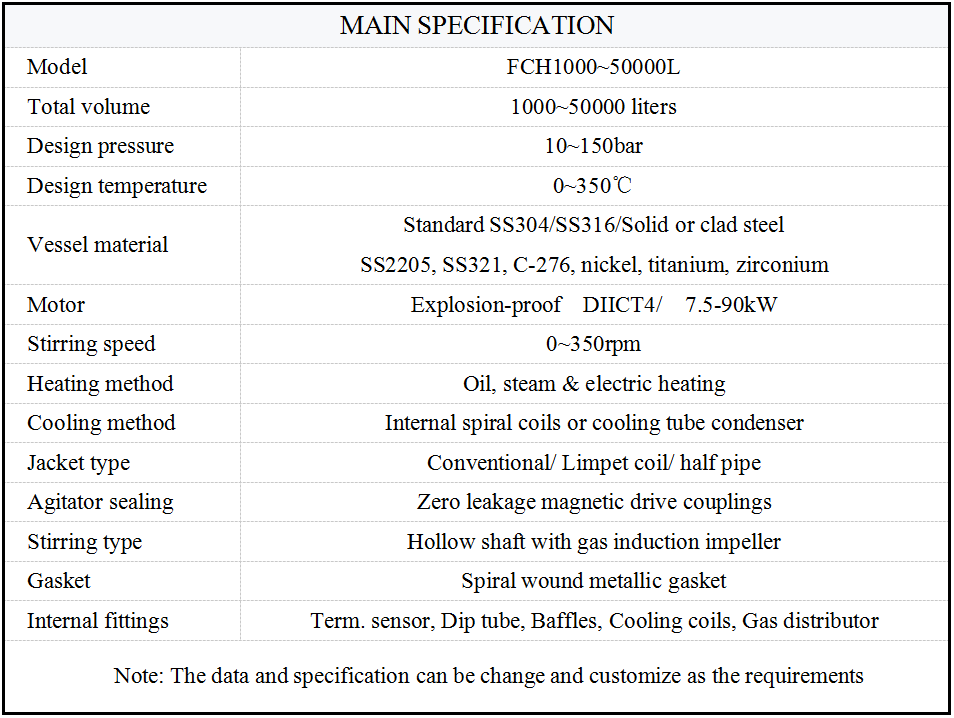

SPECIFICATION