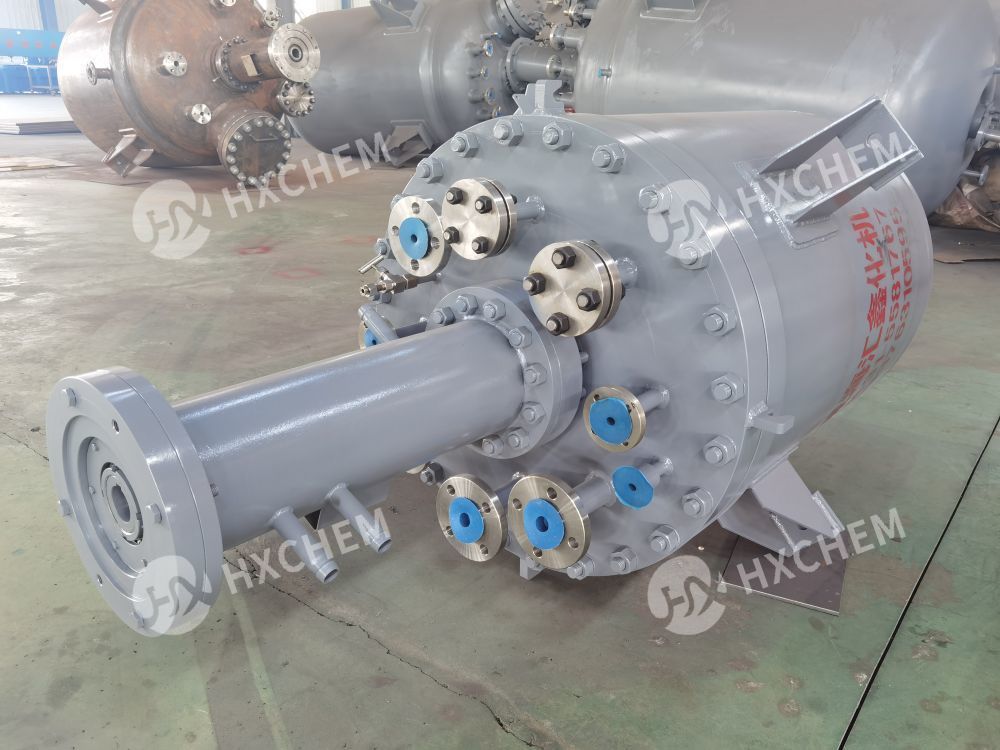

Industrial stirred hydrogenation reactor

Industrial hydrogenation reactors usually involves a three-phase slurry, the solid catalyst in slurry phase and the hydrogen bubbles as the gas phase. As there are a number of phase boundaries the mass transfer, and especially the hydrogen dispersion, is a very factor. The mixing system that is employed in the reactor influences the mass transfer coefficient of the gas-liquid transfer greatly. Industrial hydrogenation reactors; hydrogenation autoclaves; Hydrogenation reactor; Hydrogenators; stirred hydrogenation reactor

- HXCHEM

- CHINA

- 25 days after payment

- 10 SETs/MONTH

Details

Catalyst Hydrogenation Reactors/ Hydrogenators

HXCHEM is a single point solution for all that you need for various High Pressure Reactions such as Catalytic Hydrogenation, Ethoxylation Hydrogenation, Polymerization, Chlorination, Alkoxylation, Ethoxylation, Alkylation, Amination, Esterification, Bromination, Carboxylation, Oxidation, Ozonization etc. & various high pressure Gas-Liquid, Gas-Slurry or Liquid-Liquid reactions from laboratory scale, R&D, Pilot Plants to Commercial Scale Capacities.

We are manufacturer and supplier of automated and manual, stirred & non-stirred High Pressure Reactors for clients in R&D, Pharmaceutical, Bulk Drugs & Drug Intermediates, Petrochemical, Aromatic Chemicals, Agrochemicals, Fertilizers, Pesticides, Resins, Polymers, Paints, Food Colors and Chemicals, Dyes & Dye Intermediate Industries as well as in academia.

We have a team of highly qualified engineers and professionals, who have in-depth knowledge in their respective domains. This enables us to manufacture, supply and export a wide range of products for our valued clients.

We have manufactured and successfully commissioned several High Pressure Reactors/ Hydrogenators / Autoclaves along with Magnetic Drives, We have also successfullv commissioned verv high flow rates catalvst filters for noble metal catalvst like Palladium (Pd/C), Platinum(Pt/C), RhodIum, Ruthenium etc.

The hydrogenation system usually involves a three-phase slurry, the solid catalyst in slurry phase and the hydrogen bubbles as the gas phase. As there are a number of phase boundaries the mass transfer, and especially the hydrogen dispersion, is a very factor. The mixing system that is employed in the reactor influences the mass transfer coefficient of the gas-liquid transfer greatly.

Get more details about Hydrogenation.

Catalytic Hydrogenations, Industrial hydrogenation reactors; Industrial hydrogenation autoclaves; Dehydrogenation reactors, Three-phase catalytic hydrogenation reactors, Shaker Hydrogenation Apparatus, Sorbitol Production Hydrogenation Reactor, Continuous hydrogenation reactors industrial dehydrogenation reactor,stainless steel hydrogenation reactor,jacketed hydrogenation reactor, hydrogenation plants, Scale-up hydrogenation reactor, Hydrogenation

Industrial hydrogenation reactors

Volume: 100ml-20000liters.

Design pressure: maximum up to 350bar

Design temperature: Up to 350℃

Heating method: Steam/ Oil/ Electric

Wetted material:SS304, SS316 or other alloys.

Catalytic hydrogenation reactors | Stainless steel hydrogenation reactor | Hydrogenation plants

Features

Gas Induction Tech.

Gas Induction Tech. from HXCHEM

Higher gas Hold-up & mass transfer

Fine dispersion of the hydrogen

Large Gas-Liquid interfacial area

Recirculation of the unused gas

Uniform suspension of solid components (e.g., Catalyst)

Magnetic Couplings Driver

100% Sealing. Zero leakage. Low energy cost.

Various model for volume: 100ml~50m3

Long using life of bearings, less maintenance times

Full vaccum/200 bar available;

Cooling jacket set for high temperature application.

Internal Fittings Optional

Internal heating/Cooling coils: Tube type or spiral coils;

Dip tube & temperature measure tube;

Shaft, Couplings & combined stirring paddle impeller;

Gas distributor. spargers & baffles;

Optional for Pressure Vessel

Full Jacket/ Half-pipe jackets/ Dimpled jackets;

Head type:Semi-elliptical/ Dished/ Hemispherical/ Flat;

Explosive Clad Steel for anti-corrosion high pressure conditions.

Specifications

MAIN SPECIFICATION | |

Model | FCH1000~20000L |

Total volume | 1000~20000 liters |

Design pressure | 10~150bar |

Design temperature | 0~350℃ |

Vessel material | Standard SS304/SS316/Solid or clad steel SS2205, SS321, C-276, nickel, titanium, zirconium |

Motor | Explosion-proof DIICT4/ 7.5-90kW |

Stirring speed | 0~350rpm |

Heating method | Oil, steam & electric heating |

Cooling method | Internal spiral coils or cooling tube condenser |

Jacket type | Conventional/ Limpet coil/ half pipe |

Agitator sealing | Zero leakage magnetic drive couplings |

Stirring type | Hollow shaft with gas induction impeller |

Gasket | Spiral wound metallic gasket |

Internal fittings | Term. sensor, Dip tube, Baffles, Cooling coils, Gas distributor |

Note: The data and specification can be change and customize as the requirements | |

Product catagory

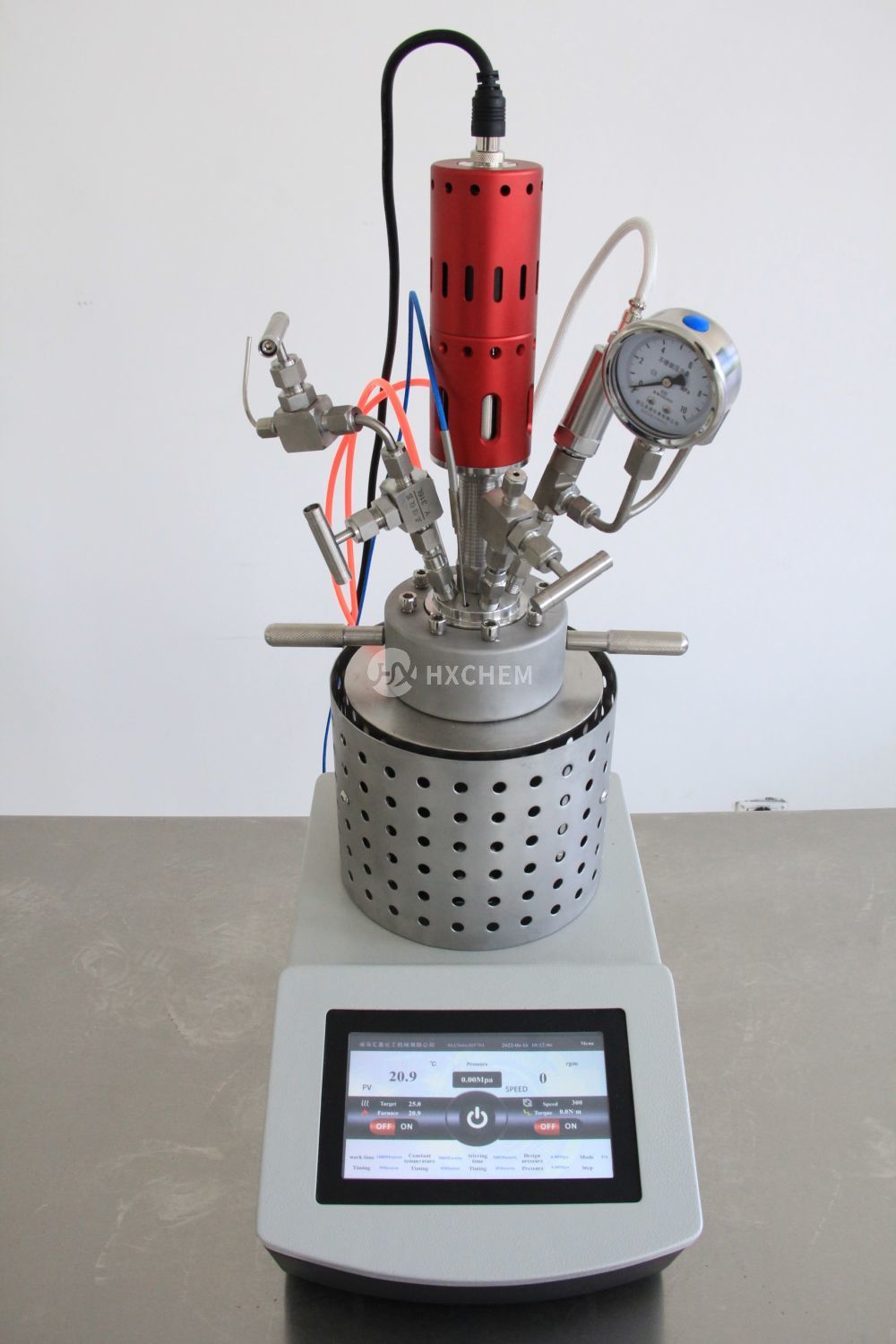

√ Bench top hydrogenation reactor (100ml-5liters)

√ Lab hydrogenation reactor (100ml-5liters)

√ Lab hydrogenation reactor with lifting (5liters- 50liters)

√ Hydrogenation pilot plant (50liters- 500liters)

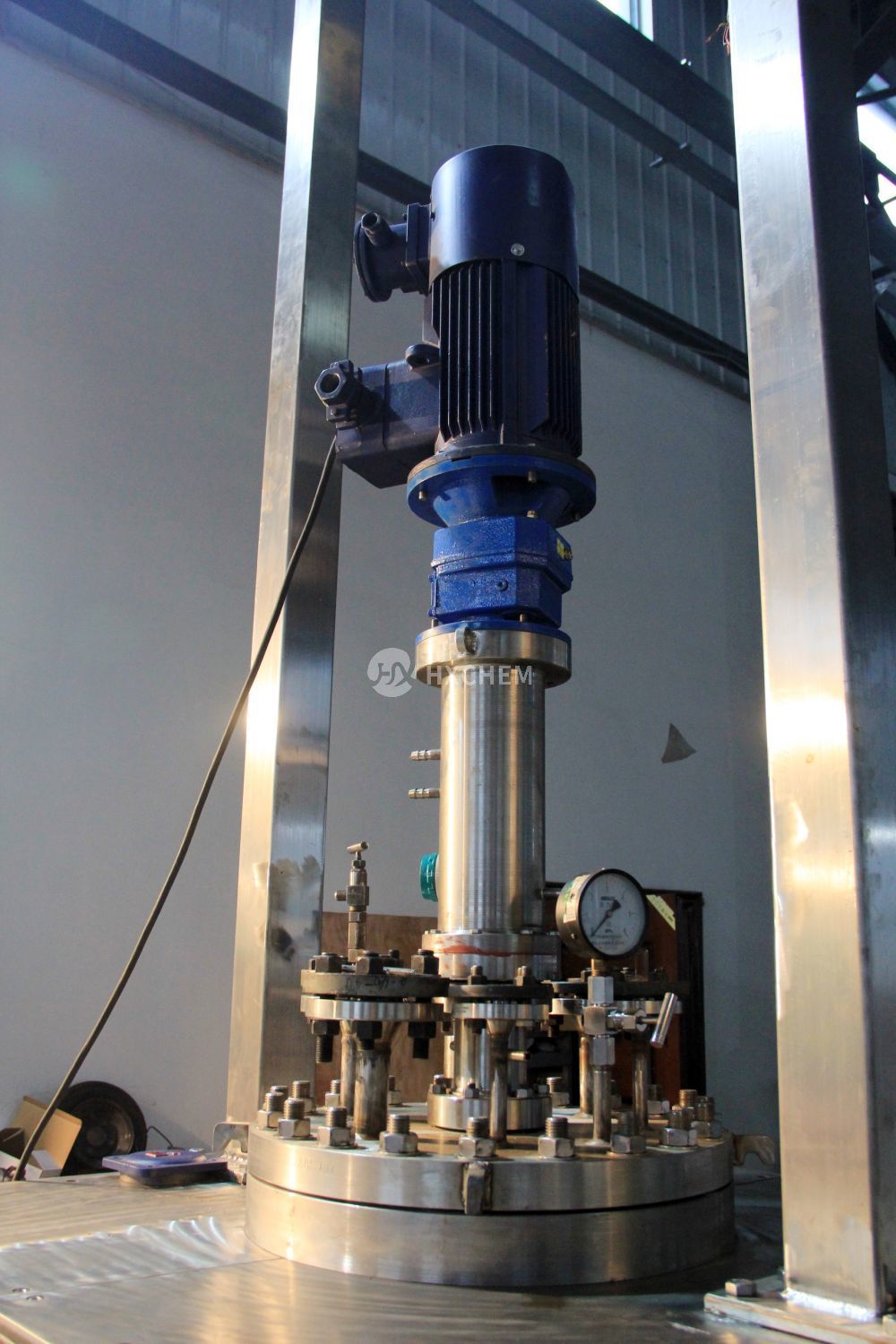

√ Industrial hydrogenation reactor (>1000liters)

Product Cases

Bench top hydrogenation Reactors / 100ml, 200ml, 500ml / 0-100bar/ 300C

GSH hydrogenation Reactors / 100ml-2liters/ 0-100bar/ 350C/ SS304/ SS316L

Hydrogenation Reactors with cover lifting & lowering, vessel body can be rotate.(100ml-5liters)

Hydrogenation Reactors with quick open device (100ml-5liters)

Hydrogenation Reactors with cover lid lifting

10liters Hydrogenation Reactors / 0-100bar/ 350C/ SS316L

20liters Hydrogenation Reactors

50liters Hydrogenation Reactors

50L-500liters Hydrogenation Reactor

100L-1000liters Hydrogenation Reactor/ C276 hydrogenation reactor

1000L-3000liters Hydrogenation Reactor

5000L-10000liters Hydrogenation Reactor

10000L-20000liters Hydrogenation Reactor

20000L-30000liters Hydrogenation Reactor