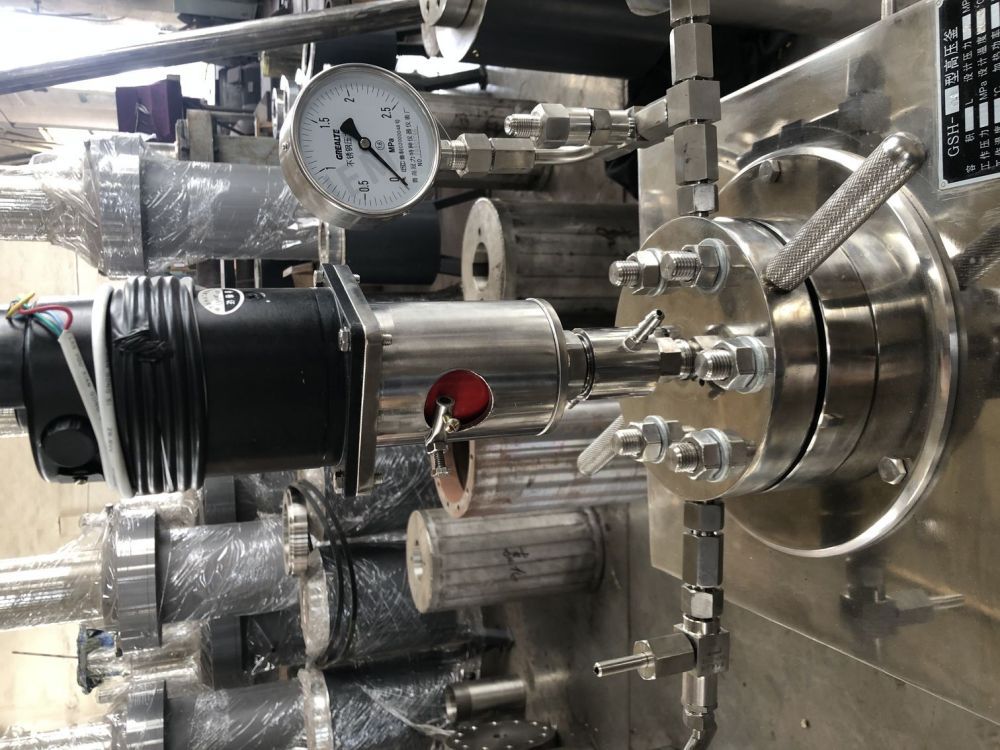

Direct Drive small scale stirred lab hydrogenation reactor

Laboratory autoclaves with 500 ml to 5 liters volume. Max pressure: 300 bar; Max temperature up to 500 ℃ Low to high torque magnetic couplings: static seal with no leakage. Magnetic couplings and motor are driven by belt. Available material:SS304, SS316, Titanium, Nickel, Hastelloy B/C, Monel, Zirconium, Inconel, Tantalum Monitor and control: Temperature, pressure, motor speed, customized, etc Safety Device (Blasting Disc) on Security Blasting Port. Customized according to customers requirement.

- HXCHEM

- China

- 7 days after payment

- 30 sets/month

Details

Direct Drive small scale stirred lab hydrogenation reactor

Introduction

This series reactor equipped with moveable cart on the basis of GSH series reactor, which is convenient for moving and portable. Same as the GSH series, with the features of magnetic seal (static seal), no leakage, smooth run, low noise and easy operation, which is widely used for various test and reaction in laboratory, under high pressure, high vacuum and high temperature condition. And sometimes it can be equipped with external condenser for distillation and vapor collection.

Application: Laboratory research, lab test and reaction under high pressure, high vacuum and high temperature condition.

2liters pressure reactors | Magnetic autoclave | High pressure chemical reactor

5liters pressure reactors | Stirred lab autoclaves | Stirred reactor plants

Product Features

Moveable cart type.

Laboratory autoclaves with 500 ml to 5 liters volume.

Max pressure: 300 bar; Max temperature up to 500 ℃

Low to high torque magnetic couplings: static seal with no leakage.

Magnetic couplings and motor are driven by belt.

Available material:SS304, SS316, Titanium, Nickel, Hastelloy B/C, Monel, Zirconium, Inconel, Tantalum

Monitor and control: Temperature, pressure, motor speed, customized, etc

Safety Device (Blasting Disc) on Security Blasting Port.

Customized according to customers requirement.

Standard specfications

GSH model laboratory pressure reactor standard specification as fellow:

| Model No. | GSH-0.1 | GSH-0.25 | GSH-0.5 | GSH-1 | GSH-2 | GSH-5 |

| Nominal Capacity | 100ml | 250ml | 500ml | 1liters | 2liters | 5liters |

| Max Working Pressure | Standard 100bar;Max pressure up to 350bar | |||||

| Working Temperature | Standard 350°C;Up to 500°C | |||||

| Stirring Speed | 0-1500rpm | |||||

| Motor Power | 150W | 150W | 150W | 0.2KW | 0.2KW | 0.6KW |

| Heating Power | 1KW | 1KW | 1KW | 2KW | 2KW | 4KW |

| Material | SS304,SS316 or other alloys(Titanium, hastelloy, Inconel, Nickel, etc) | |||||

| Heating Method | Standard Electric heating ( Thermal oil recycling, far infrared heating optional ) | |||||

| Cooling | Internal spiral coils(optional) | |||||

| Charging Method | Up discharge by pressure or discharge by bottom valve | |||||

| Stirring type | Propeller, paddle type, turbine, anchor type, gas induction, helix type, etc. | |||||

| Control panel | Temp.display and control, accuracy+ 1℃, Stirring speed display & control Touch screen program control(Optional) | |||||

| Standard fittings | Pressure Gage, Thermocouple, Central stirring port Liquid inlet/ Sampling port with needle valve & dip tube and gas inlet with needle valve Safety Rupture Disc: Internal cooling Coil(Optional); Solid feeding plug(Optional) | |||||

Product Details

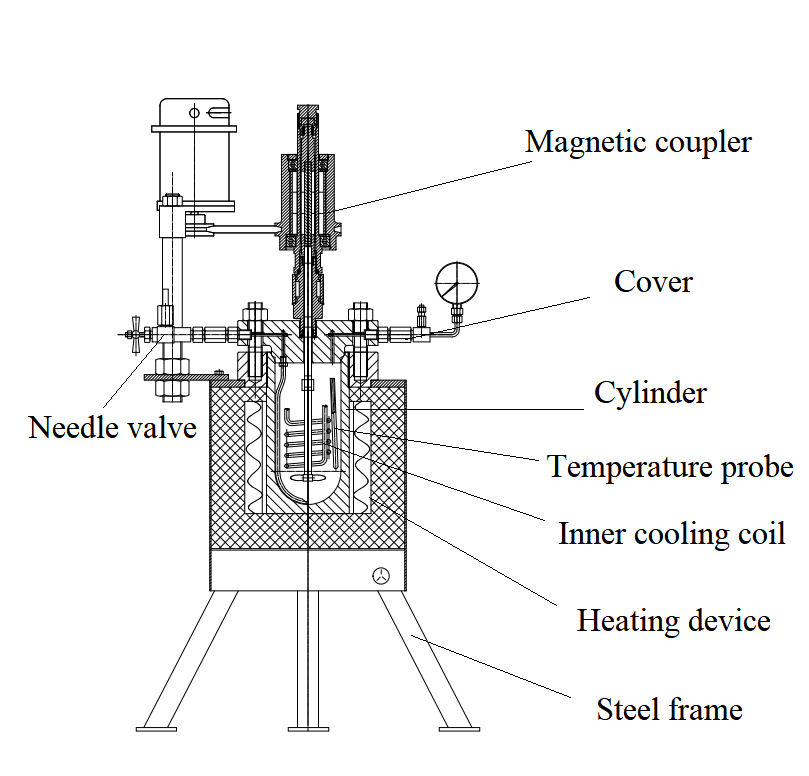

Stucture Drawings

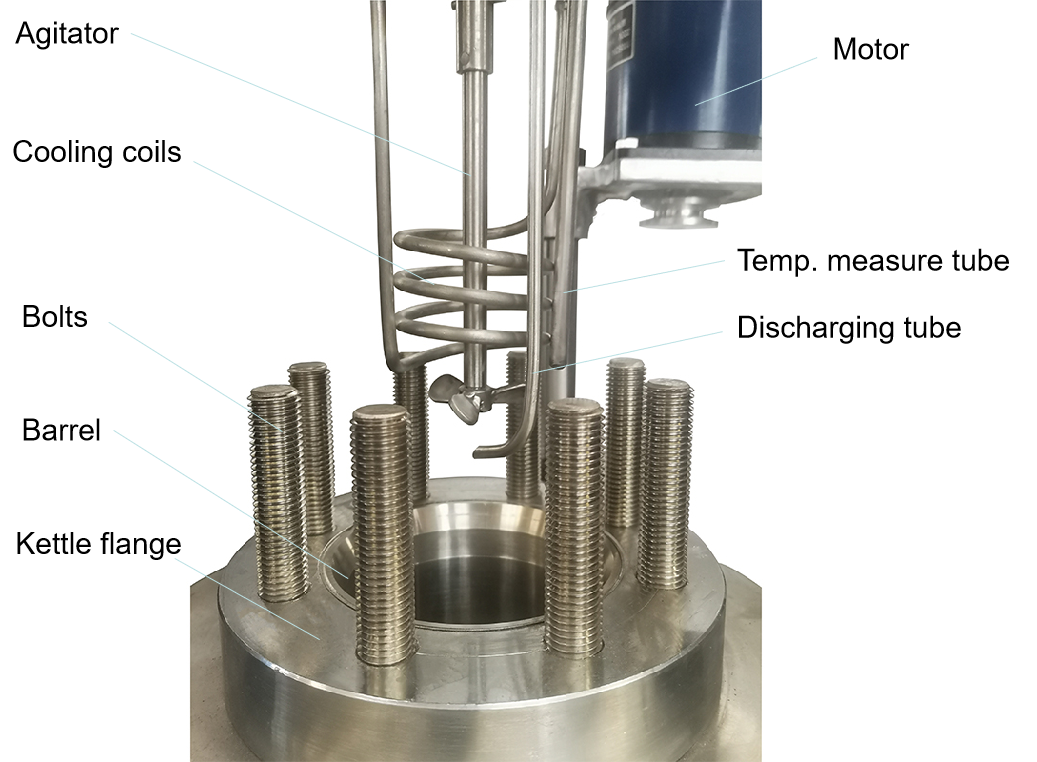

Magnetic Couplings

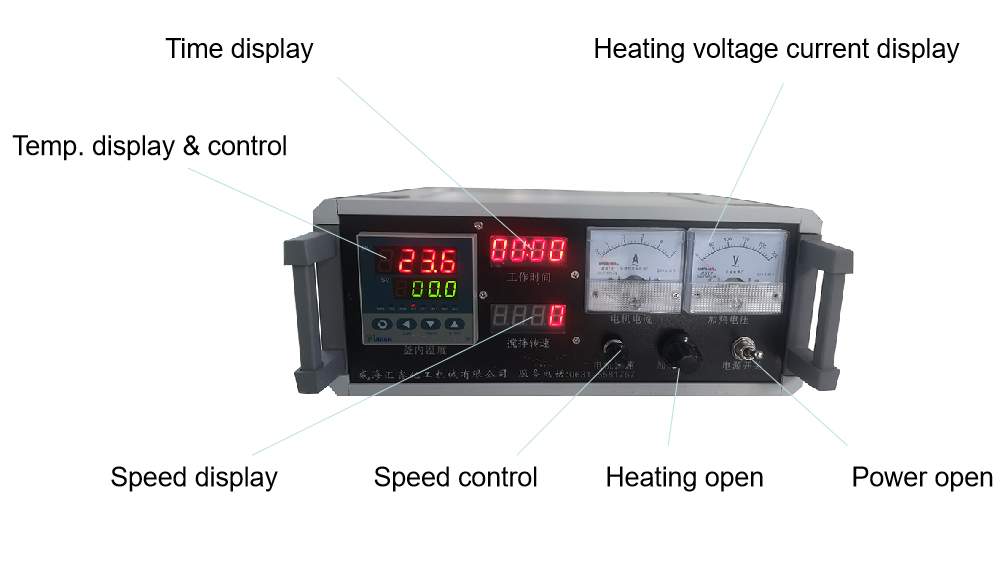

Control System

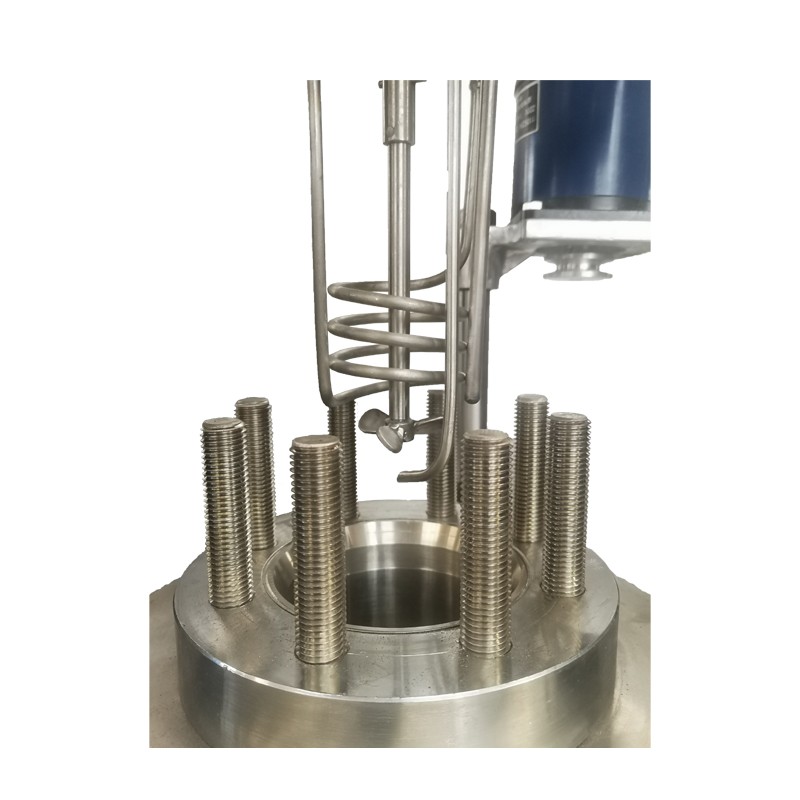

Internal Components

Delivery Details

Departure Port:Qingdao Port or Shanghai Port

Time of Delivery:

Name | Est.time (Days) |

Lab instru. | <7 |

Pilot plant | <20 |

Industrial | <40 |

Note:The specific delivery date subject to product specifications and quantity.

Payment Terms:

Payment amount | ≤10000USD | >10000USD |

Payment term | 100% TT in advance | 40% T/T in advance, balance before shippment. |

Other type | Paypal;Alibaba | 100% Irrevocable L/C at Sight |

Note: The specific payment terms will be confirmed through negotiation.

Package type:

Wooden Box Packaging (Standard export package)

Application: By air; LCL(Less container loading) by sea.

Details:The product will be covered by PE film, then packed in plywood case. If necessary, steel frame outside support and steel wire inside fixing.