Duplex steel cladded reactor vessels

Duplex steel cladded reactor vessels; Duplex steel 2507 reactor; Duplex steel 2205 reactor; Duplex steel cladded reactor; Duplex steel cladded vessels; Duplex steel cladded reactor vessels; Duplex steel reactor vessels

- HXCHEM

- China

- 45 days after payment

- 5sets/ month

Details

Duplex steel cladded reactor vessels

Introduction

Duplex steel reactor is used especially for chloride-containing process fluids and for ammonium carbamate solutions. In a strongly alkaline chloride- bearing solution, duplex SS gives excellent performance whilst a high-nickel alloy fails after three year because of chloride. Given their excellent corrosion resistance, higher strength and lower cost duplex stainless steels are an attractive alternative to austenitic stainless steel. In oxygen-free carbamate solutions, duplex has proved to be even more corrosion resistant than much more costly materials such as titanium and high-nickel alloys; Application: Chloride-containing solutions; Ammonium carbamate solutions; Nitric acid and acidic ammonium nirate solutions.

Duplex steel cladded reactor vessels; Duplex steel 2507 reactor; Duplex steel 2205 reactor; Duplex steel cladded reactor; Duplex steel cladded vessels; Duplex steel cladded reactor vessels; Duplex steel reactor vessels

Product Features

Large scale production- maximum volume reach to 50m3

Max pressure: 200 bar; Max temperature up to 300 ℃

Material:Duplex steel 2205, 2507

Chloride-containing solutions where the typical austenitic stainless steels are susceptible to stress corrosion cracking and corrosion fatigue.

When cladding plates be considered, including base material for strength and clad material for anti-corrosion. Reduce costs for you!

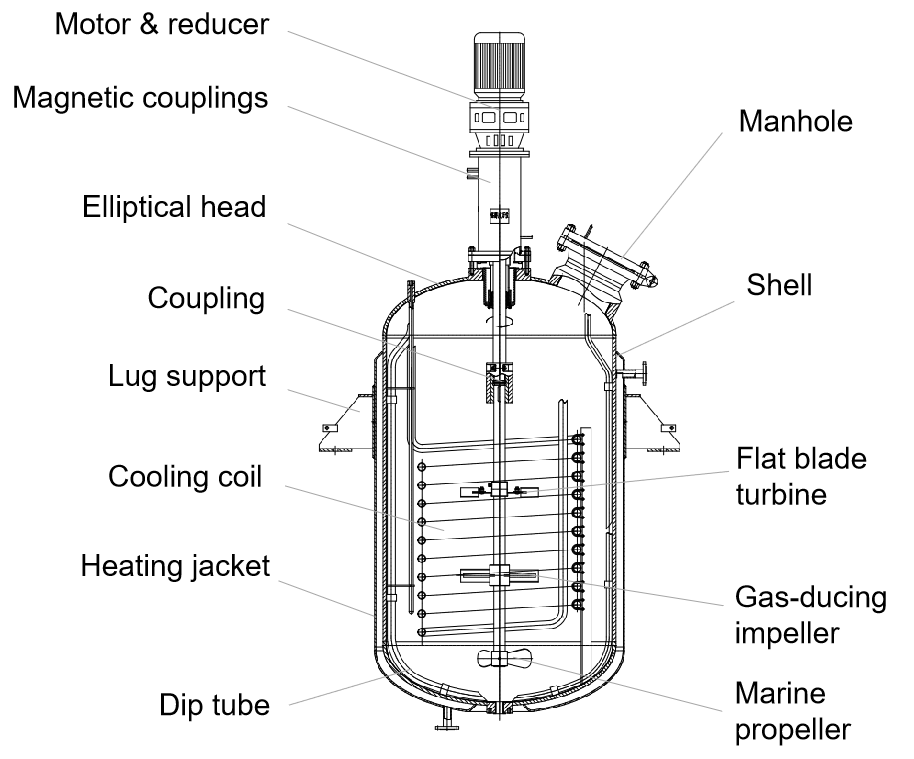

Internal cooling coil, vent port, liquid / powder charging, dip tube, thermowell, safety rupture disc, pressure safety valve, flush bottom outlet, baffles, light & sight glass, handhole / manhole etc. Nozzles, manual / automated valves, fittings, control panel & accessories offered based on requirement.

Lugs or floor stand leg support.

Customizations

If there has special process requires,HXHCEM will also customize for you!

Pls list your basis process parameters like follows:

1. Reactor volume

2. Operating Temperature

3. Operating Pressure

4. Reactor Material / contacting components material (Solid or cladding?)

5. Agitator type, and the Mixing Speed, motor power request?

6. With heating Jacket or not? Jacket type?

7. Internal cooling coil or not, exchange area?

8. Your other requests

9. Design code requirements?

......Contact us

We like to help you to accomplish your plans.

Product Details