Lab scale direct drive magnetic reactor

Floor stands or moveable cart type. Laboratory autoclaves with 500 ml to 5 liters volume. Max pressure: 300 bar; Max temperature up to 500 ℃. Low to high torque magnetic couplings: static seal with no leakage. Direct drive type between magnetic couplings and motor. Available material:SS304, SS316, Titanium, Nickel, Hastelloy B/C, Monel, Zirconium, Inconel, Tantalum Smooth run, beautiful appearence, low noise and easy operation. Monitor and control: Temperature, pressure, motor speed, gas / liquid flow, level, etc Safety Device (Blasting Disc) on Security Blasting Port. Customized according to customers requirement.

- HXCHEM

- China

- 10 days after payment

- 30 sets/month

- 常规实验室釜.pdf

Details

Lab scale direct drive magnetic reactor

Introduction

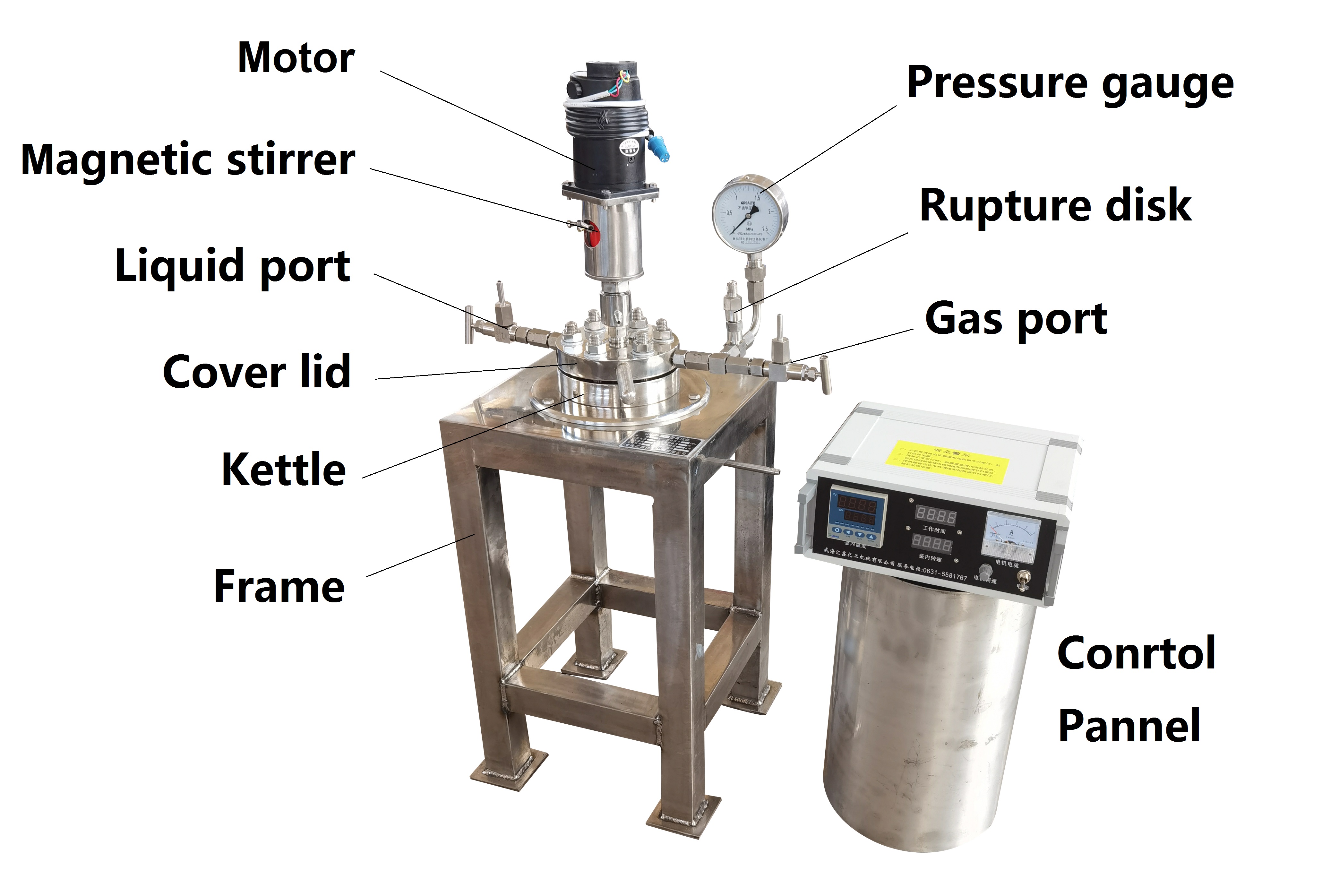

500ml 1L 2L 5L lab scale direct drive magnetic reactor is designed for the reaction of lab research and small production. Safety features guarantee safe reactions under pressure. Various low to high torque magnetic drives ensure efficient mixing and stirring low to high viscosity process media as well as excellent heat transfer. Magnetic couplings seal (static seal) have advantages of no leakage, smooth run, low noise and easy operation, which is widely used for various chemical reaction in laboratory, under high pressure, high vacuum and high temperature condition. And Sometimes can be equipped with condensers for vapor escape and distillation process.

Customizable autoclave reactor | Reaction autoclave | Custom autoclave reactor

Batch autoclave reactor | Catalytic autoclave reactor | Autoclave reactor vessel

Product Features

Floor stands or moveable cart type.

Laboratory autoclaves with 500 ml to 5 liters volume.

Max pressure: 300 bar; Max temperature up to 500 ℃.

Low to high torque magnetic couplings: static seal with no leakage.

Direct drive type between magnetic couplings and motor.

Available material:SS304, SS316, Titanium, Nickel, Hastelloy B/C, Monel, Zirconium, Inconel, Tantalum

Smooth run, beautiful appearence, low noise and easy operation.

Monitor and control: Temperature, pressure, motor speed, gas / liquid flow, level, etc

Safety Device (Blasting Disc) on Security Blasting Port.

Customized according to customers requirement.

Standard Specifications

Item | GSH-0.5 | GSH-1 | GSH-2 | GSH-3 | GSH-5 |

Nominal Capacity (L) | 0.5 | 1 | 2 | 3 | 5 |

Working Pressure (MPa) | 10 | 10 | 10 | 10 | 10 |

Working Temperature(℃) | 350 | 350 | 350 | 350 | 350 |

Stirring Speed (r/min) | 0-1500 | 0-1500 | 0-1500 | 0-1500 | 0-1500 |

Motor power (kW) | 0.15 | 0.2 | 0.2 | 0.2 | 0.6 |

Heating Power (kW) | 1 | 2 | 2 | 3 | 4 |

Heating Method | General electric heating(water recycling, thermal oil heating available) | ||||

| Cooling Method | Spiral coils(Single coils, serpentine coils available) | ||||

| Charging Method | Charging from above | ||||

| Stirring type | Propeller, paddle type, anchor type or customized | ||||

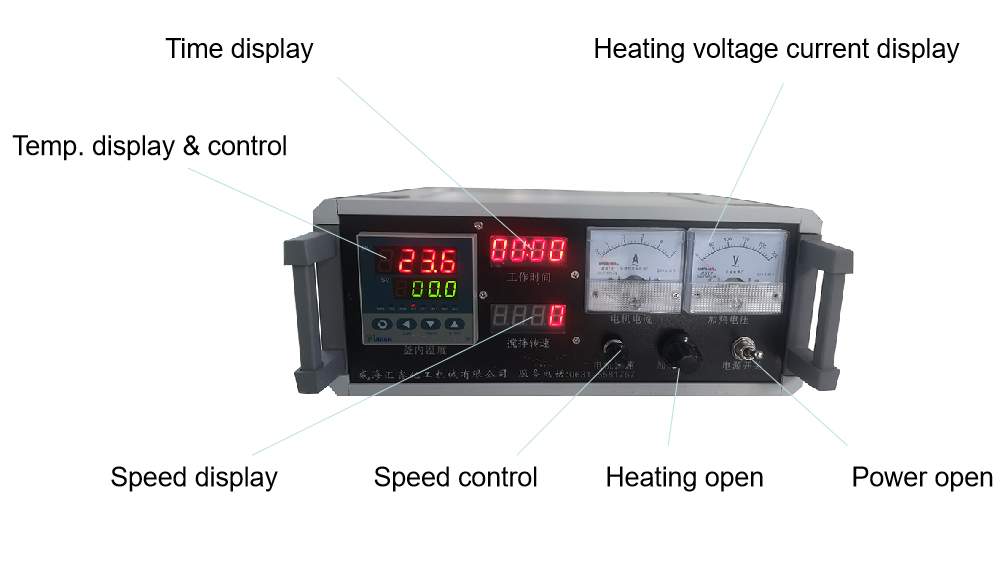

Control panel | Temperature, time and heating voltage display Temperature adjustment control, accuracy±1 ℃ Stirring speed display and control | ||||

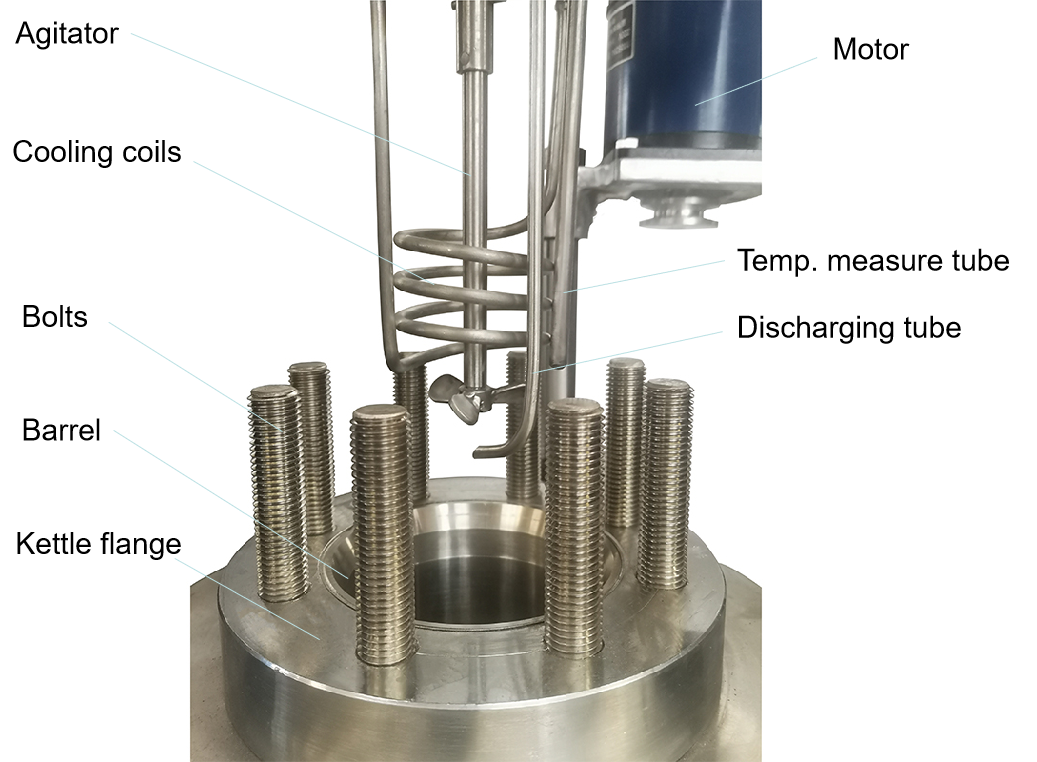

| Standard fittings | Pressure Gage; Thermocouple; Internal Stirring System Liquid inlet and gas inlet with needle valve;Gas Release Valve Dip Tube; Safety Rupture Disc; Cooling Coil | ||||

Product Details

Structure Drawings

Control System

Internal Components