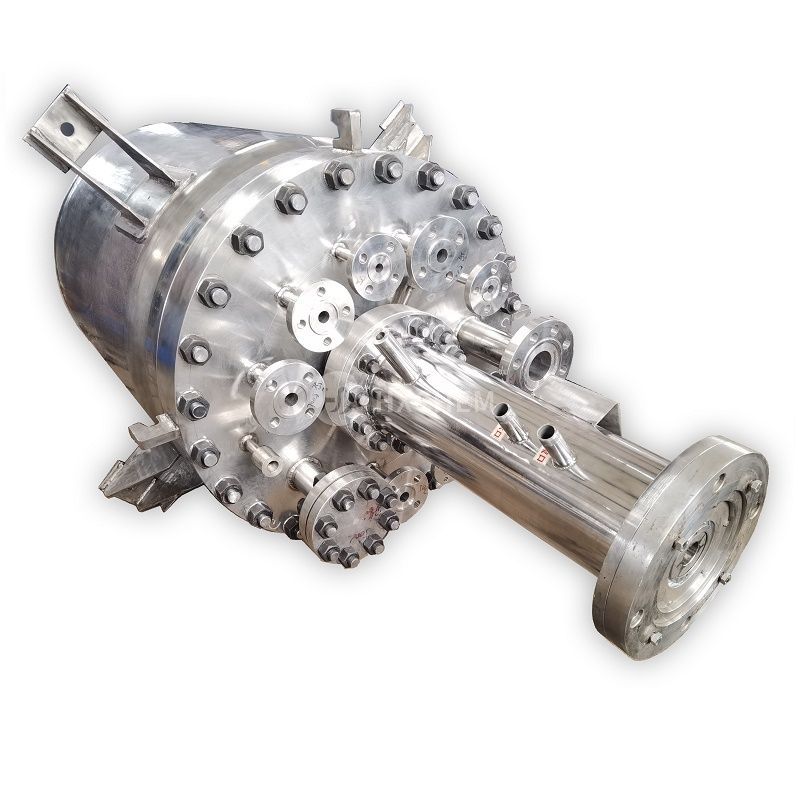

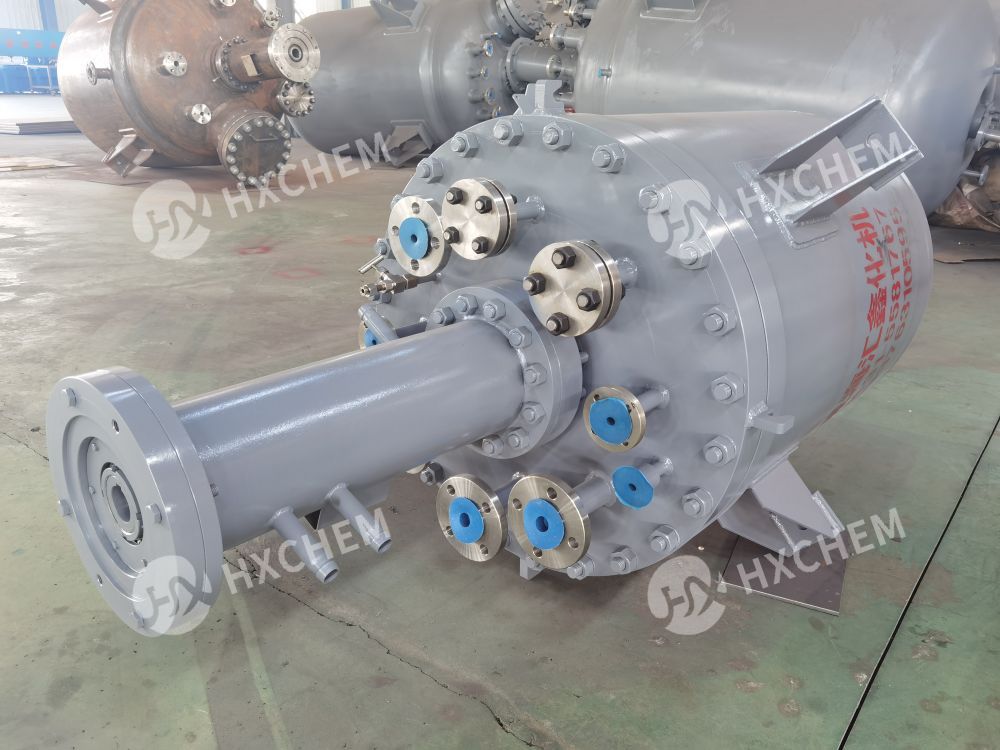

Flat cover closure stirred pressure autoclaves

This series are standard GSH model pilot scale pressure autoclaves; flat cover closure type, Stirred autoclaves, Pilot scale stirred pressure autoclaves and stirred pressure autoclaves. These autoclave equipped with magnetic coupling drive agitator and cover lid, flange bolts and nuts closure, internal fittings optional for various reaction.

- HXCHEM

- China

- 60 days after payment

- 30 sets/month

Details

Flat cover closure stirred pressure autoclaves

Pilot scale pressure autoclaves/stirred pressure autoclaves

Introduction

This series are standard GSH model pilot scale pressure autoclaves; flat cover closure type, Stirred autoclaves, Pilot scale stirred pressure autoclaves and stirred pressure autoclaves.

These autoclave equipped with magnetic coupling drive agitator and cover lid, flange bolts and nuts closure, internal fittings optional for various reaction.

Stirred pressure autoclaves | High pressure stirred autoclaves | High pressure chemical reactor

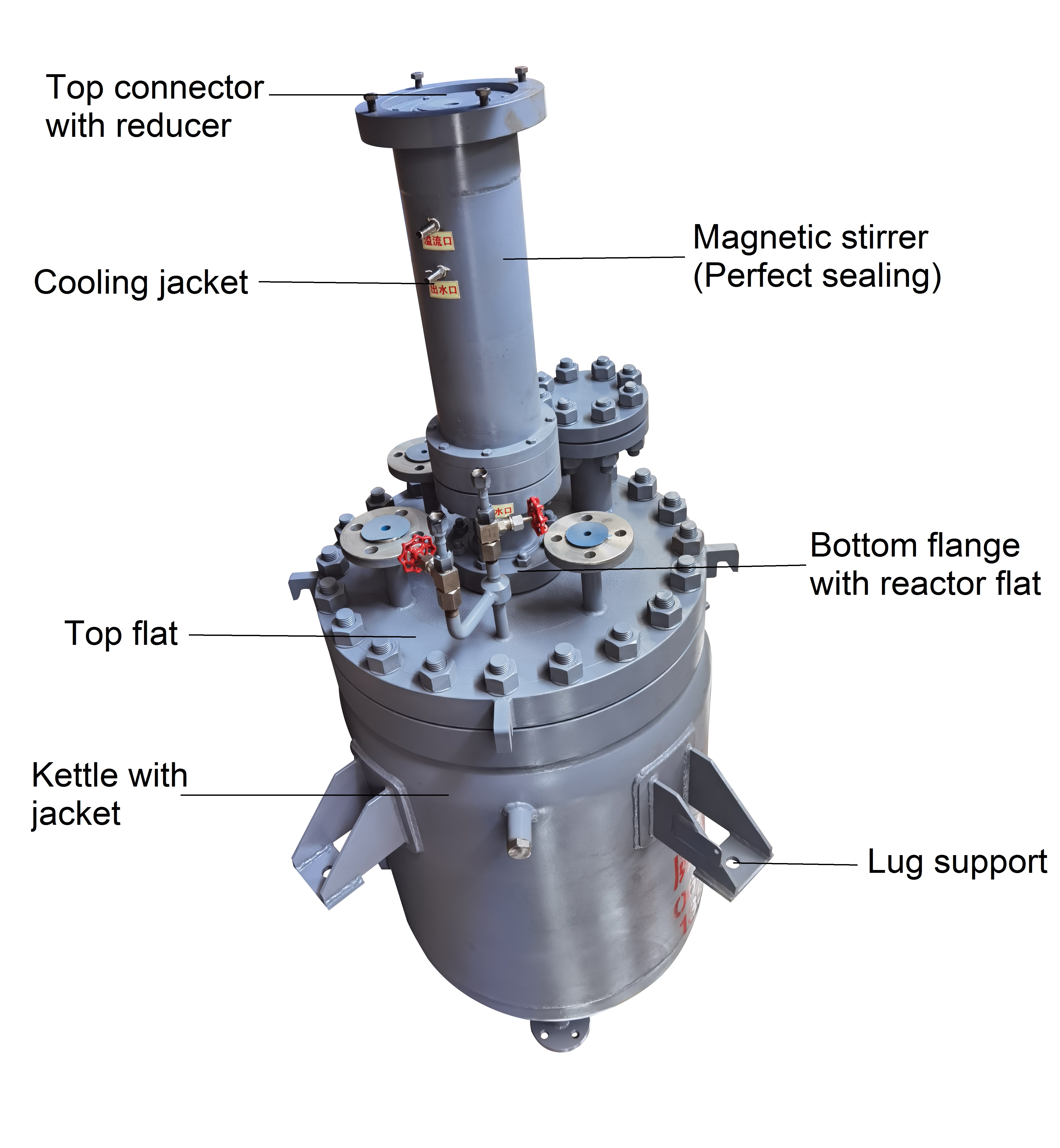

Product Features

Lug support flat cover closure pilot pressure autoclave

Capacity volume:100litres; 200litres; 300litres, 500litres

Max pressure: 100 bar; Max temperature up to 300 ℃

Low to high torque magnetic couplings: static seal with no leakage.

Wet material:SS304, SS316, Titanium, Nickel, Hastelloy B/C, Monel, Zirconium, Inconel.

Standard Specifications

GSH pilot pressure reactor standard specification

| GSH-50 | ||||

| 50 | ||||

Standard 100bar, -0.1-250 bar customized | ||||

SS304 or SS316 wetted parts, other alloys (Titanium, Hastelloy, Duplex steel, etc.) | ||||

0~350 customize based on operate temp. | ||||

| 0-500 | ||||

| 1.5 | ||||

According to the working temperature | ||||

Standard electric heating(Thermal oil, steam, far infrared heating available) | ||||

Flat cover or elliptical flange closure | ||||

Propeller, paddle, anchor, spiral, turbine, gas inducing type, etc | ||||

Spiral cooling cools with cooling water | ||||

Discharging from bottom or above. | ||||

PID temperature display and control, accuracy±1 ℃; Stirring speed display; Operation time display; Heating voltage and current display; Touch screen optional. | ||||

Pressure gauge, Safety valve port; Temp. measuring port; Gas and liquid port; Dip tube; Vent port; Solid charging port; Cooling coil inlet and outler port; | ||||

Note:The above standard parameters are for reference only. Different processe have their own reasonable selection, not the more complete the function, the better.

The structure, specification, nozzle size and orientation need to be confrimed after communicating with us.