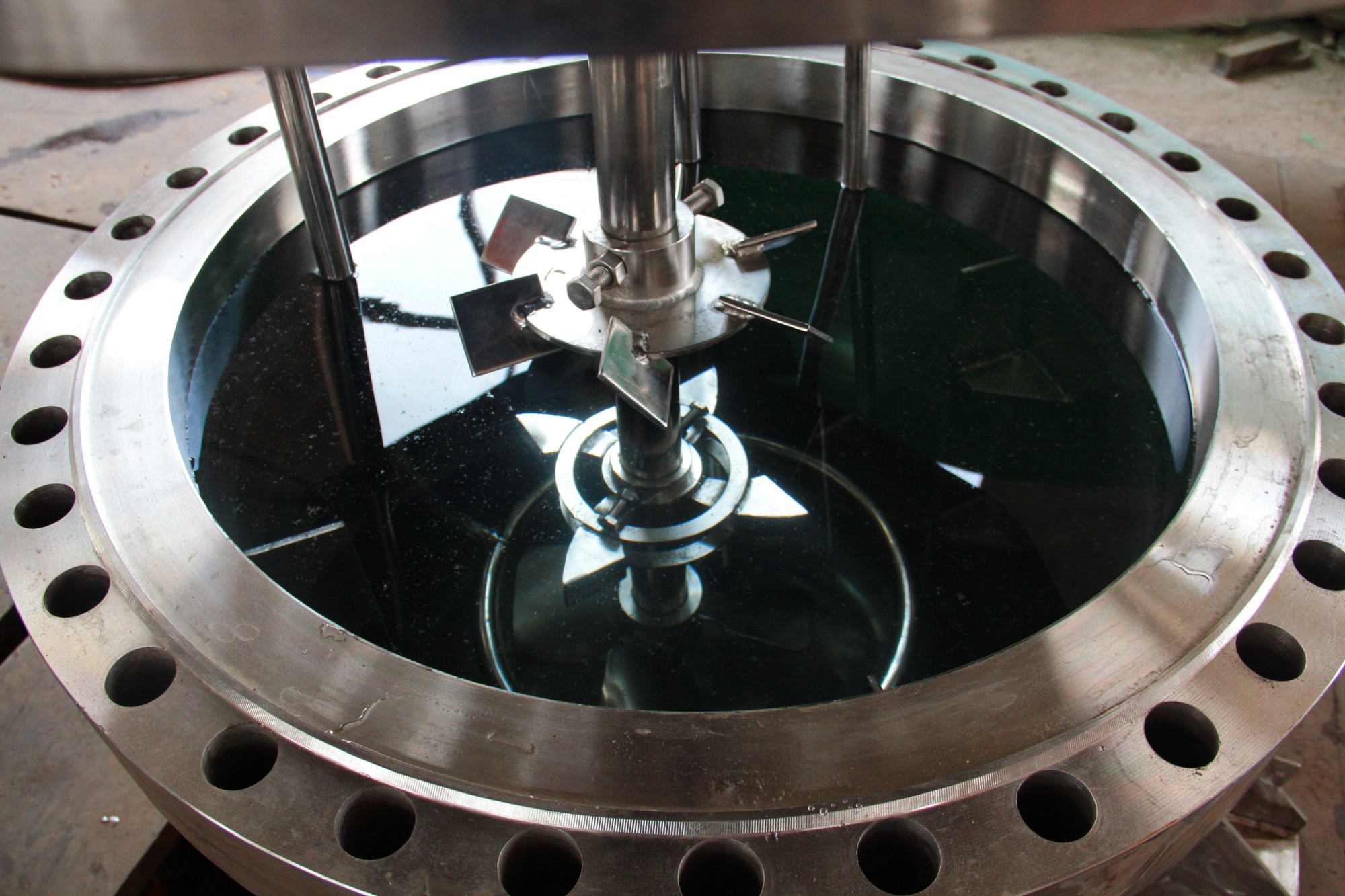

High pressure hastelloy cladding pilot reactor

High pressure hastelloy cladding pilot reactor; hastelloy cladding pilot reactor; hastelloy cladding reactor; High pressure pilot reactor;300L pressure reactors; hastelloy reactors | Most of GSH reactors adopt flat covers, especially for the lab and pilot scale production, because of its good sealing, easy operating and cleaning, which is suitable for the high pressure and high temperature conditions.

- hxchem

- china

- 30 days after payment

- 40 sets/month

Details

100liters to 1000liters hastelloy clad pressure reactors

100L; 200L; 300L; 500L; 1000L pressure reactors

Introduction

This series pilot reactor is specially used in high pressure process, especially hydrogenation process. The magnetic coupling drive (static seal), no leakage, smooth run, low noise and easy operation, which is widely used for high pressure, high vacuum and high temperature condition. The wet parts of pressure autoclave can be made in SS316L, Hastelloy C276, SS2205, etc.

Reactor volume: 100 – 1000 liter

Pressure: -1 /FV) to +100 bar

Temperature: -20 °C to +350 °C

Material: Stainless steel, Hastelloy clad C276, etc.

Other materials, pressures & temperatures are available.Autoclave are built for pressure reactions as well as for reactions under full vacuum. Different technologies and materials are used, depending on the requested process and process media.

Pilotclave pressure reactors range from 100-1000 liters and are all customized. To quote such systems we require detailed specifications. Safety is important with such larger scale systems, especially when doing hydrogenations and other reactions under higher pressure. The degree of automation and process control vary from simple data collection to complete automation of the system. In most cases, the reaction vessels are jacketed steel or Hastelloy reactors.

Pilot plant manufacturers | Pilot plant& Reactor system | Medium-scale pressure reactors

Pilot batch reactor | Pilot reactor systems | Chemical reactor vessel

Product Feature

Floor stands or moveable cart type.

Capacity volume: 100 liters to 1000 liters .

Max pressure: 150 bar; Max temperature up to 350 ℃

Low to high torque magnetic couplings: static seal with no leakage.

Lifting device available for reactor head rising and lowering.

Top Head type: Flat cover; Bottom head type: Ellipsoidal type.

Available material:SS304, SS316, Titanium, Nickel, Hastelloy B/C, Monel, Zirconium, Inconel.

Monitor and control: Temperature, pressure, motor speed, operating time, etc.

Customized according to customers requirement.

GSH pilot pressure reactor standard specification

| GSH-50 | ||||

| 50 | ||||

Standard 100bar, -0.1-250 bar customized | ||||

SS304 or SS316 wetted parts, other alloys (Titanium, Hastelloy, Duplex steel, etc.) | ||||

0~350 customize based on operate temp. | ||||

| 0-500 | ||||

| 1.5 | ||||

According to the working temperature | ||||

Standard electric heating(Thermal oil, steam, far infrared heating available) | ||||

Flat cover or elliptical flange closure | ||||

Propeller, paddle, anchor, spiral, turbine, gas inducing type, etc | ||||

Spiral cooling cools with cooling water | ||||

Discharging from bottom or above. | ||||

PID temperature display and control, accuracy±1 ℃; Stirring speed display; Operation time display; Heating voltage and current display; Touch screen optional. | ||||

Pressure gauge, Safety valve port; Temp. measuring port; Gas and liquid port; Dip tube; Vent port; Solid charging port; Cooling coil inlet and outler port; | ||||

Note:The above standard parameters are for reference only. Different processe have their own reasonable selection, not the more complete the function, the better.

The structure, specification, nozzle size and orientation need to be confrimed after communicating with us.

Customized Specifications

If there has special process requires,HXHCEM will also customize for you!

Pls list your basis process parameters like follows:

1. Reactor volume

2. Operating Temperature

3. Operating Pressure

4. Reactor Material / contacting components material

5. Agitator type, and the Mixing Speed, motor power request?

6. With heating device or not.

7. Internal cooling coil or not, exchange area?

8. Lifting device or not?

9. Your other requests

......Contact us

We like to help you to accomplish your plans.

Application