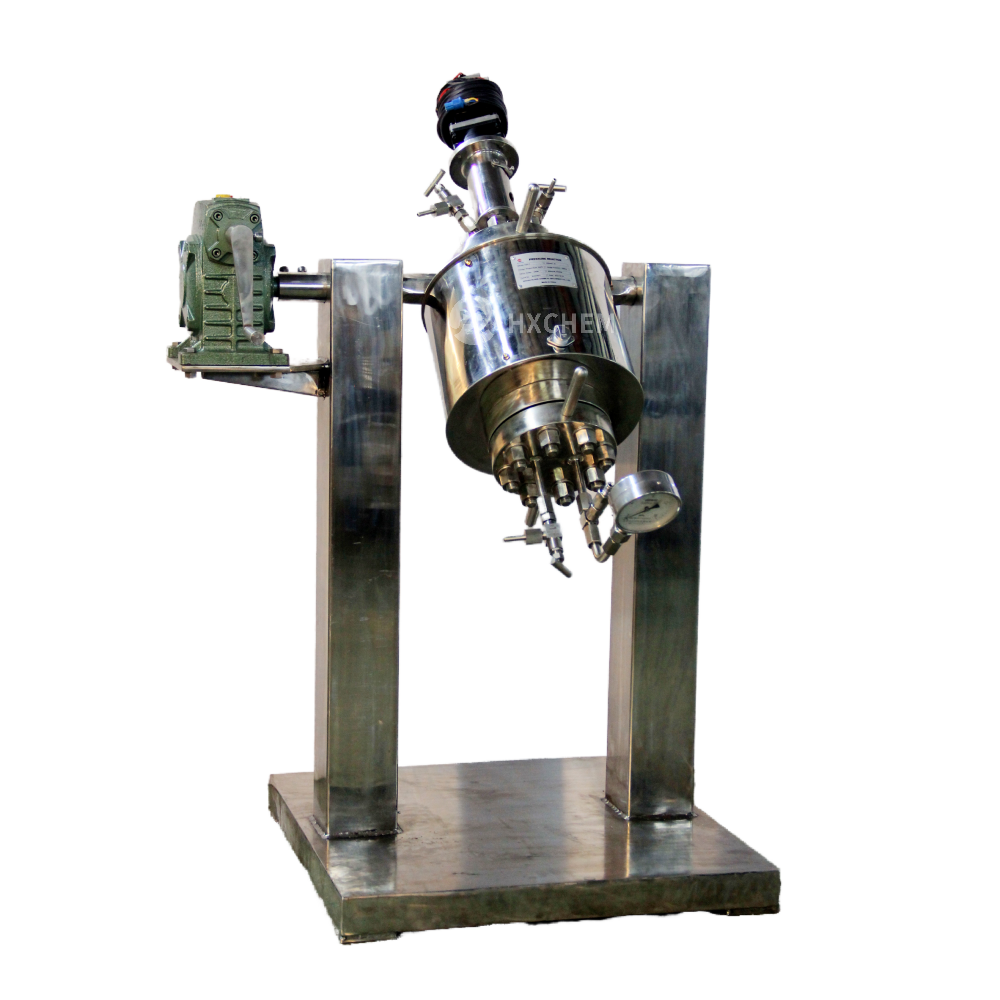

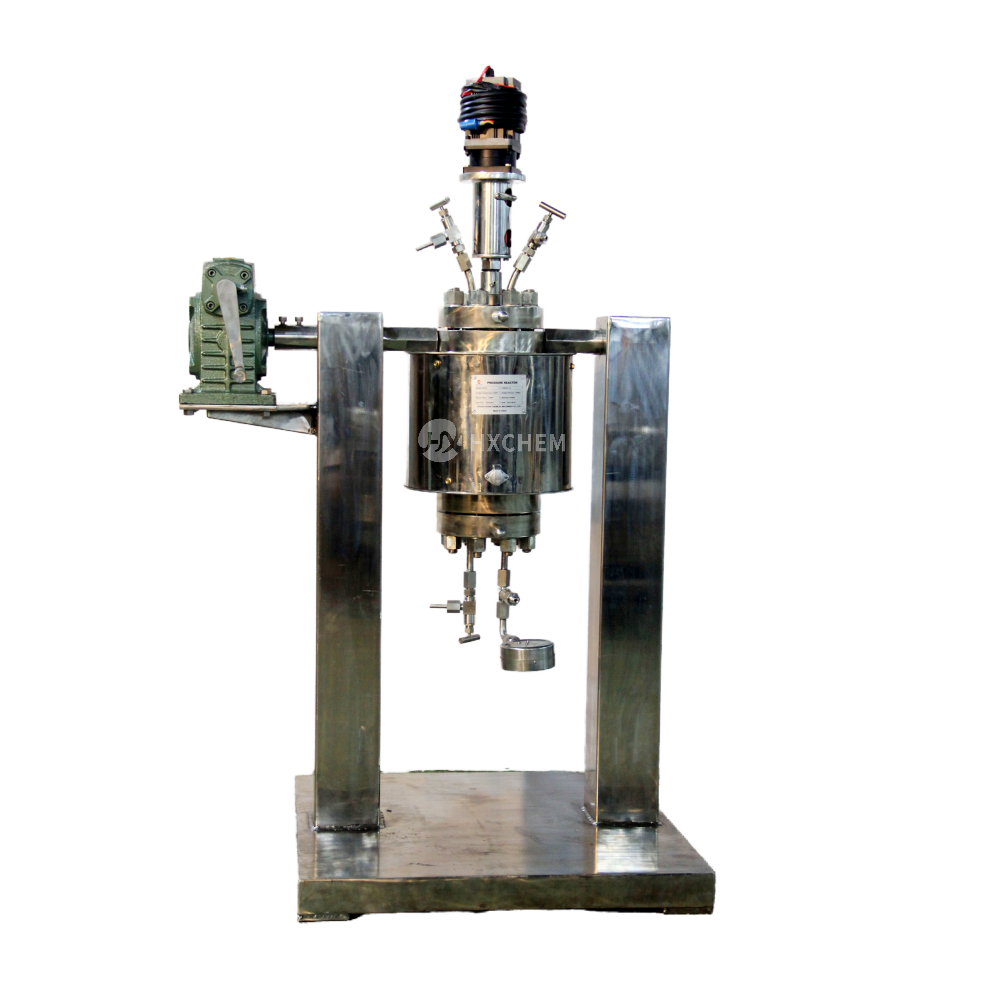

Horizontal stirred high pressure autoclave with rotate device

Equipment for use in chemical process development must meet a wide range of requirements, such as resistance to temperature, pressure and aggressive media.laboratory and pilot plant systems/Laboratory Apparatus Engineering Laboratory pressure autoclave | Small scale pressure reactors | Customizable autoclave reactor Autoclave reactor design | High pressure stirred reactors/ high pressure autoclave/ Horizontal pressure reactor/ Horizontal stirred reactor/ Pyrolytic kettle/ Pyrolytic reactor

- HXCHEM

- China

- 30 days after payment

- 40 sets/month

Details

Horizontal stirred pressure autoclave

Pyrolytic reactor/Autoclave

Introduction

* plants* wood pulp* wood chips* fibers

Horizontal pressure reactors | Horizontal pressure autoclaves | High temperature autoclave reactor

Autoclave reactor price | High pressure chemical reactor | Custom autoclave reactor

Features

In the horizontal position, the internal stirrers tumble the material rather than try to stir it with a standard vertical stirrer. These custom reactors are secured vertically for loading and then safely tilted horizontally for stirring. They can also be designed to be operated in both a horizontal and vertical position.

This one liter reactor is loaded vertically and can be stirred vertically or horizontally. A heavy-duty stirring motor and double anchor stirrers are shown. Another available option is to add a tilt mechanism to the cylinder for discharge. The autoclave reactor equipped with pressure gauge and rupture disc. And the high pressure magneitc coupling driven agitator can helps reactor works under high temperature and high pressure.

Standard specfications

GSH pressure reactor standard specification table.

| Model No. | GSH-0.1 | GSH-0.25 | GSH-0.5 | GSH-1 | GSH-2 | GSH-5 |

| Nominal Capacity | 100ml | 250ml | 500ml | 1liters | 2liters | 5liters |

| Max Working Pressure | Standard 100bar; Max pressure up to 350bar | |||||

| Working Temperature | Standard 350°C;Up to 500°C | |||||

| Stirring Speed | 0-1500rpm | |||||

| Motor Power | 150W | 150W | 150W | 0.2KW | 0.2KW | 0.6KW |

| Heating Power | 1KW | 1KW | 1KW | 2KW | 2KW | 4KW |

| Closure | Flange bolts closure/ Clamp closure | |||||

Lifting & lowering (Optional) | Cover lid lifting, Vessel fixed Cover lid manual lifting, Vessel rotation Vessel lifting & lowering, vessel rotation Manual; Electric driven; Pneumatic; Hydraulic (Driven method) | |||||

| Material | SS304,SS316 or other alloys(Titanium, hastelloy, Inconel, Nickel, etc) | |||||

| Heating Method | Standard Electric heating ( Jacket heating, far infrared heating optional ) | |||||

| Cooling | Internal spiral coils(optional) | |||||

| Charging Method | Up discharge by pressure or discharge by bottom valve | |||||

| Stirring type | Propeller, paddle type, turbine, anchor type, gas induction, helix type, etc. | |||||

| Control panel | Temp.display and control, accuracy+ 1℃, Stirring speed display & control Touch screen program control(Optional) | |||||

| Standard fittings | Pressure Gage, Thermocouple, Central stirring port Liquid inlet/ Sampling port with needle valve & dip tube and gas inlet with needle valve Safety Rupture Disc: Internal cooling Coil(Optional); Solid feeding plug(Optional) | |||||