Polybutylen terephtalate PBT esterification reactor

Esterification reactor; Lab esterification reactor; Laboratory esterification reactor; Polybutylen terephtalate PBT esterification reactor; Laboratory or pilot reactor for polymerization of the polybutylen terephtalate PBT; BDO and DMT reaction pressure reactor;Distillation systems have packing column shell and tube; horizontal condenser

- HXCHEM

- China

- 45 days after payment

- 15sets/ month

Details

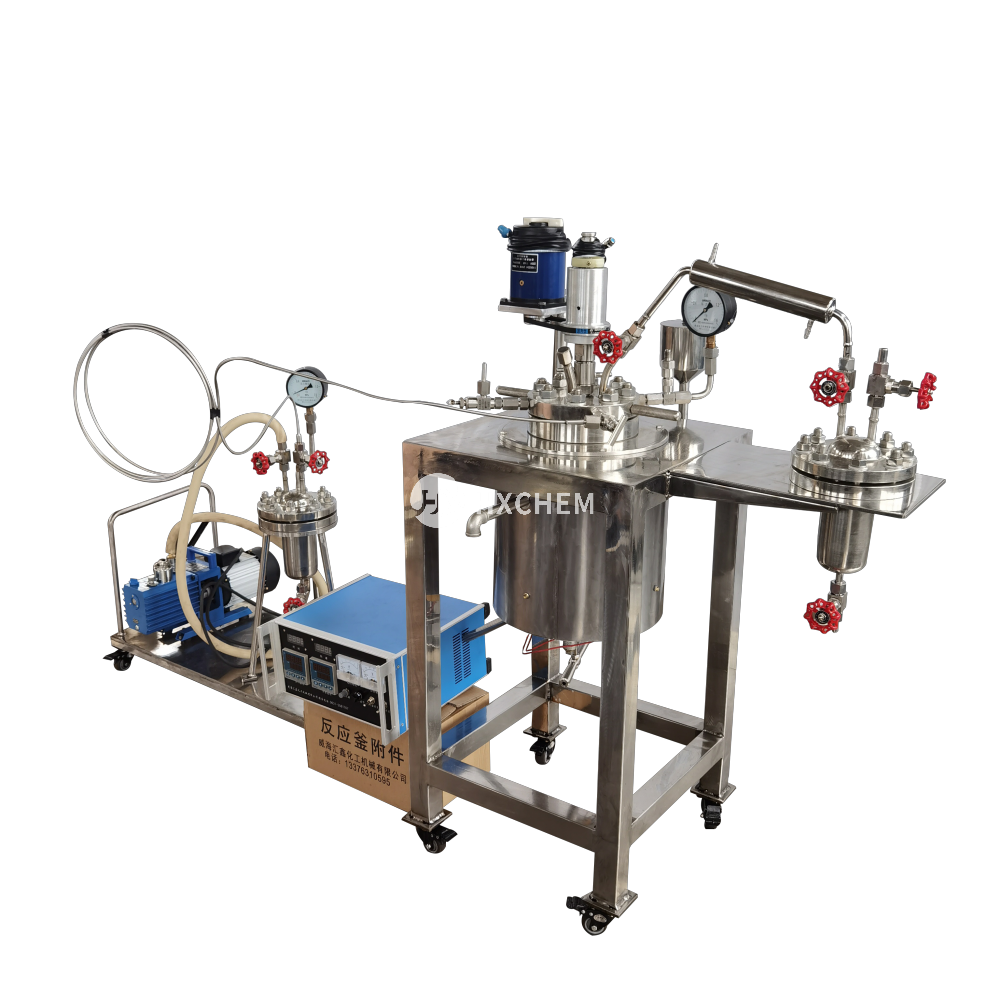

Polybutylen terephtalate PBT esterification reactor

Esterification reactors are widely used in the production of various esters, such as esters of fatty acids, which are commonly used in the manufacture of detergents, lubricants, and other chemical products. They are also employed in the synthesis of flavor and fragrance compounds, as well as in the production of biodiesel fuel from vegetable oils and animal fats. The esterification reactor typically consists of a reaction vessel, heating and cooling systems, agitation devices, and other ancillary equipment. The reaction vessel is where the esterification reaction takes place, and it is usually made of materials that can withstand high temperatures and pressures. The heating and cooling systems are used to control the reaction temperature, while the agitation devices ensure uniform mixing of the reactants and promote efficient reaction kinetics.

Product Features

* Floor stands or moveable cart type.

* Laboratory autoclaves with 100 ml to 50 liters volume.

* Max pressure: 35 bar; Max temperature up to 300 ℃

* Available material:SS304, SS316

* Low to high torque magnetic couplings: static seal with no leakage.

* Reflux model:Equipped with external condenser, reflux tube line.

* Receiving model:Equipped with external condenser, receiving tank.

* Bottom drain valve optional;

* Monitor and control: Temperature, pressure, motor speed, working time, etc

* Safety Device (Blasting Disc) on Security Blasting Port.

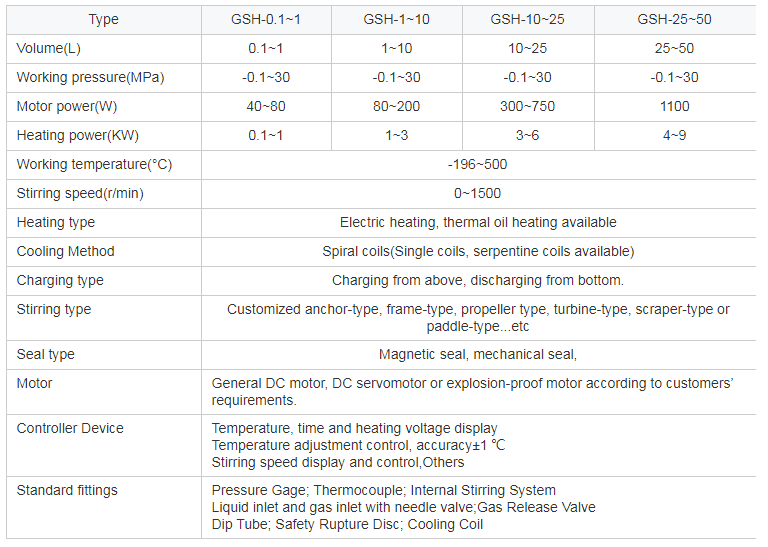

Product Parameters