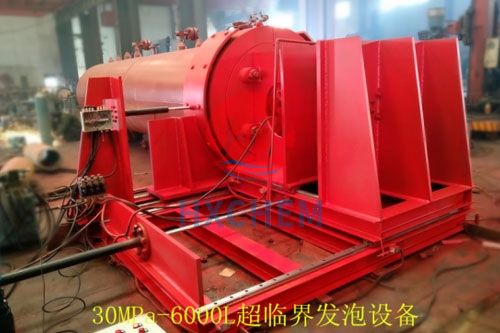

Supercritical CO2 foaming equipment

General design temperature is 150 ℃, 30 mpa design pressure. Foam particles still working temperature 130 ℃, pressure < 15 mpa, 20 mpa design pressure, design temperature 200 ℃.

- HXCHEM

- China

- 60 days after payment

- 40 sets/month

Details

Supercritical CO2 Foaming Equipment

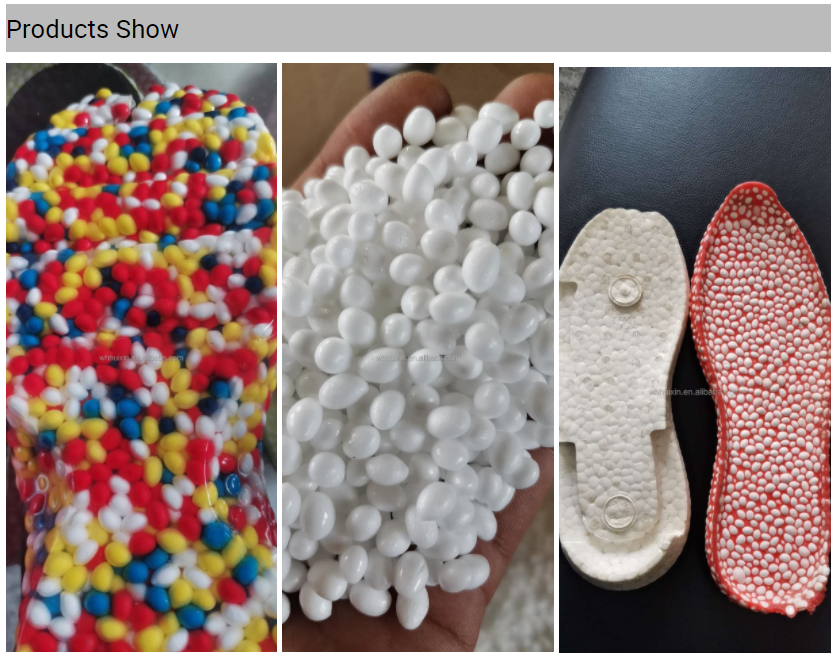

Supercritical foaming technology is a kind of new foaming technology developed in recent years, which USES supercritical carbon dioxide and nitrogen to inflate granular or plate-like TPU materials (commonly known as foaming). It is mainly used for TPU (thermoplastic polyurethane elastic rubber) foaming. It is mainly used to make the sole material of all kinds of high-grade sports shoes, and also can be used in the industrial fields such as packing material, cushion gasket, packing material, vibration damping material and automobile interior decoration material. This material has been widely used because of its high elasticity (resilience rate can reach over 61%), high strength, high toughness, high abrasion resistance, high yellow resistance, anti-aging, low density (0.15-0.25g/cm3), good low-temperature performance, non-toxic, tasteless, and pollution-free process.

General design temperature is 150 ℃, 30 mpa design pressure.

Foam particles still working temperature 130 ℃, pressure < 15 mpa, 20 mpa design pressure, design temperature 200 ℃. Because it is gas solid liquid three kinds of material mix fully, need to use agitator device, general use magnetic stirrer.

Product Features

* Two kinds of gas pipelines, which respectively meet the supply of CO2 and N2;

*The kettle body is sealed with a self-tightening seal and a safety interlock device ensures zero pressure operation to avoid injury. There are overpressure and overtemperature alarm devices. The PLC will perform pressure reduction and temperature treatment when it encounters overpressure and overtemperature;

Product Paramenters

Device size | Effective volume | Design Features |

Experimental | 1~10L | Small-scale scientific research needs of various materials; Process pipelines can be changed and expanded according to user needs; Equipped with safety devices keep safe and reliable; Excellent performance, easy operation and the experimental data is stable and reliable; |

Pilot production | 10~500L | Unique structure design; Uniquely designed quick-opening structure, good airtightness, simple; Use a variety of high-quality fittings to avoid cross-contamination of dyes; High self-control level, stable and reliable product quality and experimental data, suitable for industrial amplification to obtain design basis; |

Industrial production | 500L~ | The design will be based on the actual needs of the customer to design a specific process route and configuration plan, and then industrialized amplification implementation. |

Delivery Details

Departure Port:Qingdao Port or Shanghai Port

Time of Delivery:

Name | Est.time (Days) |

Lab instru. | <7 |

Pilot plant | <20 |

Industrial | <40 |

Note:The specific delivery date subject to product specifications and quantity.

Payment Terms:

Payment amount | ≤10000USD | >10000USD |

Payment term | 100% TT in advance | 40% T/T in advance, balance before shippment. |

Other type | Paypal;Alibaba | 100% Irrevocable L/C at Sight |

Note: The specific payment terms will be confirmed through negotiation.

Package type:

Wooden Box Packaging (Standard export package)

Application: By air; LCL(Less container loading) by sea.

Details:The product will be covered by PE film, then packed in plywood case. If necessary, steel frame outside support and steel wire inside fixing.