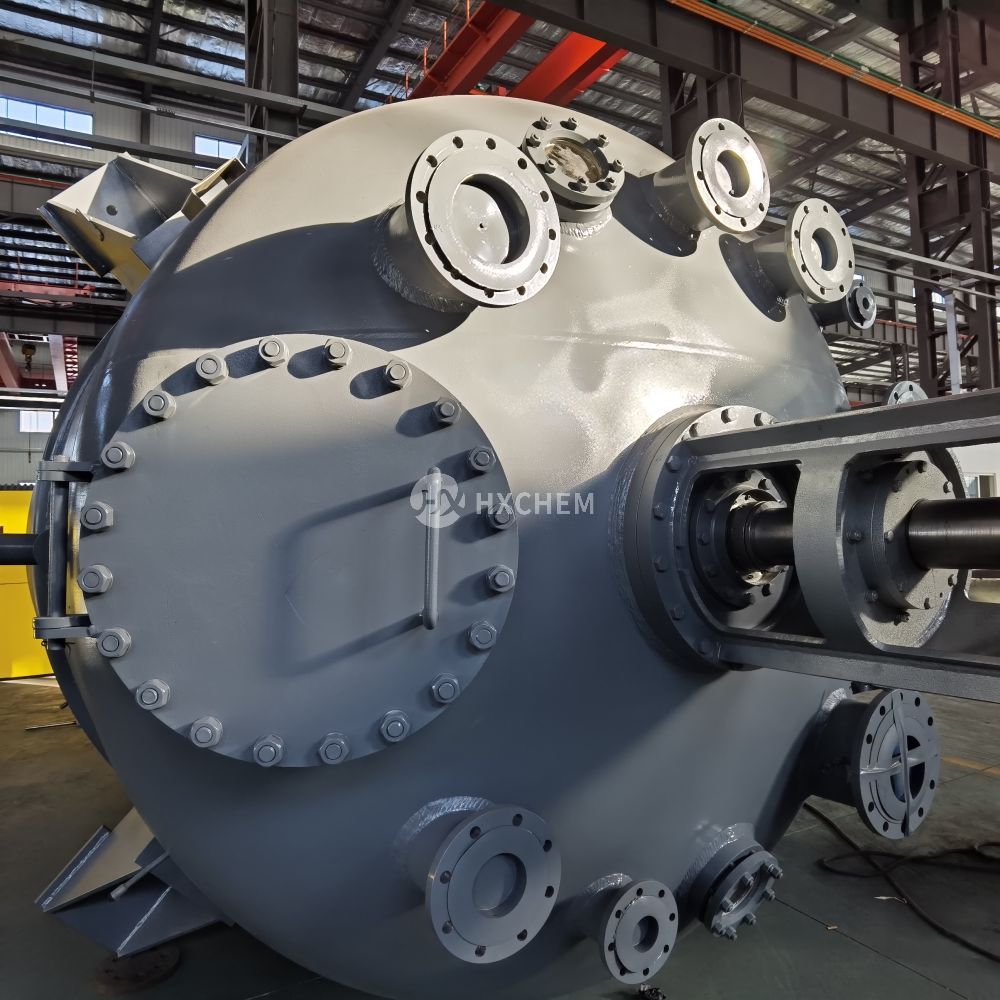

Titanium alloy cladding reactor

Titanium reactor/ Titanium clad reactors/ Titanium cladding reactor/ Titanium cladded reactor/ Titanium reactor vessels/ Titanium clad reactor | Chemical titanium reactor | Titanium hydrogenation reactor

- HXCHEM

- CHINA

- 100 days after payment

- 10 SETs/MONTH

Details

Titanium reactors/ Titanium cladded reactors

Titanium Reactors are very often specified for highly-corrosive industrial applications and are frequently used in processes in which chlorides are a component. Designs Titanium Reactors with Solid construction, Explosive clad, Standard jacket, Half pipe jacket, Baffles, Tray rings and Dip tubes.

Volume: 1000-500000liters.

Design pressure: maximum up to 80bar

Design temperature: Up to 315℃

Material:Titanium cladding sheet.

Titanium clad reactor | Titanium pressure reactor | Titanium autoclave reactor | Large scale Titanium alloy reactor | Industrial chemical titanium reactor

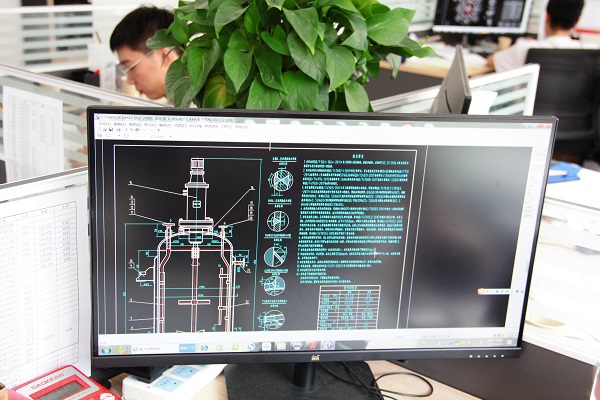

Reactor Designs

Base data

Working volume/ Material;

Working pressure/ temperature;

Heating method: Steam/ Oil/ Electric;

Seal type: Magnetic or mechanical;

Internal fittings

Internal heating/Cooling coils: Tube type or spiral coils;

Dip tube & temperature measure tube;

Shaft, Couplings & combined stirring paddle impeller;

Gas distributor. spargers & baffles;

Optional for pressure vessel

Solid Wall/ Full Jacket/ Half-pipe jackets/ Dimpled jackets;

Head type:Semi-elliptical/ Dished/ Hemispherical/ Flat;

Explosive clad steel for anti-corrosion high pressure conditions.

Construction Materials(Titanium)

Weights light and high strength

High resistance to stress corrosion cracking, corrosion fatigue and erosion

Ability to withstand hot/dry and cold/wet acid gas loading

Excellent resistance to corrosive and erosive action of high-temperature acid steam and brine

Note: Titanium cladding plates could be considered when pressure is large, base material for strength and titanium clad for anti-corrosion.

CORROSION RESISTANCE

Chlorine Chemicals; Hydrochloric Acid/ Phosphoric Acid ; Sea Water/ Sulfuric Acid/ Nitric Acid.

Customizations

If there has special process requires,HXHCEM will also customize for you!

Pls list your basis process parameters like follows:

1. Reactor volume

2. Operating Temperature

3. Operating Pressure

4. Reactor Material / contacting components material (Solid or cladding?)

5. Agitator type, and the Mixing Speed, motor power request?

6. With heating Jacket or not? Jacket type?

7. Internal cooling coil or not, exchange area?

8. Your other requests

9. Design code requirements?

......Contact us

We like to help you to accomplish your plans.