5-29liter lab stirred pressure reactor

5-29liters stirred pressure reactors; stirred pressure reactor; Pressure reactors; 5liters reactor; 10liters reactor; lab stirred pressure reactor Standard 100bar @350℃ Wet material: SS316L, 316Ti, Hastelloy C276, Titanium, etc. Non contact material: Carbon steel Equipped with manual lifting devices Stirred pressure reactor/ Hydrogenation reactor/ pressure autoclave/ Magnetic pressure reactor

- HXCHEM

- CHINA

- 20 days after payment

- 30 SETS PER MONTH

Details

5-29liter stirred pressure reactor

Pressure autoclave/ Lab pressure reactor

5-29liters stirred pressure reactors; stirred pressure reactor; Pressure reactors; 5liters reactor; 10liters reactor; lab stirred pressure reactor. These kinds laboratory stirred pressure reactor is widely applicated in high pressure and high temperature reaction of laboratory test.

Reactor volume: 5L, 10L, 20L, 29liters

Pressure: -1 (FV) to +100 bar

Temperature: 20 °C to +350 °C

Wet Material: Stainless steel 304/316, Hastelloy C276, Titanium

Other materials, pressures & temperatures are available.

Features

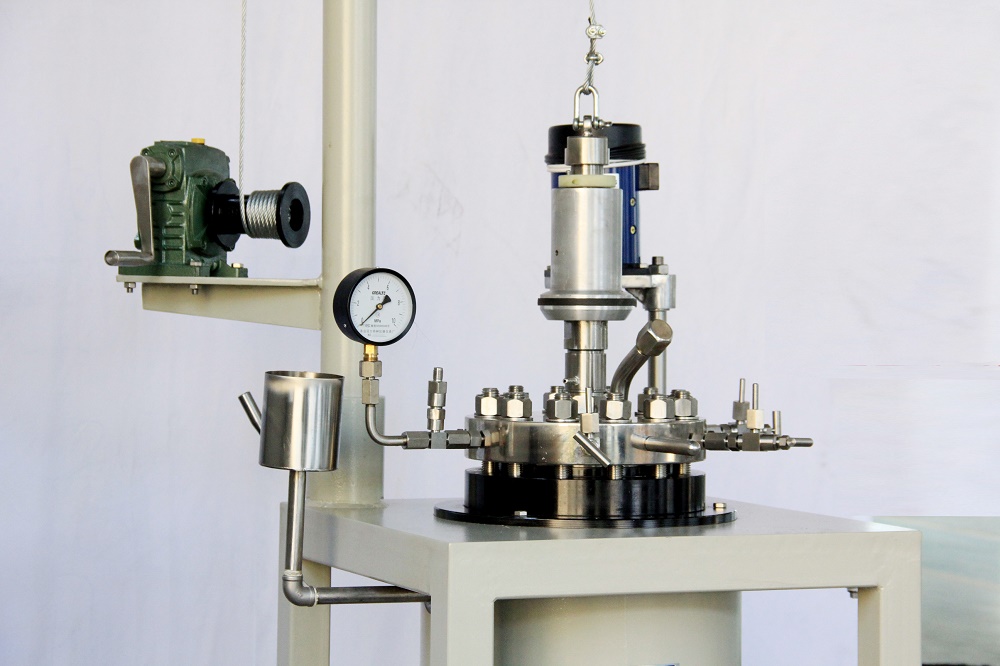

● Flat cover lid: Manual lifting & lowering

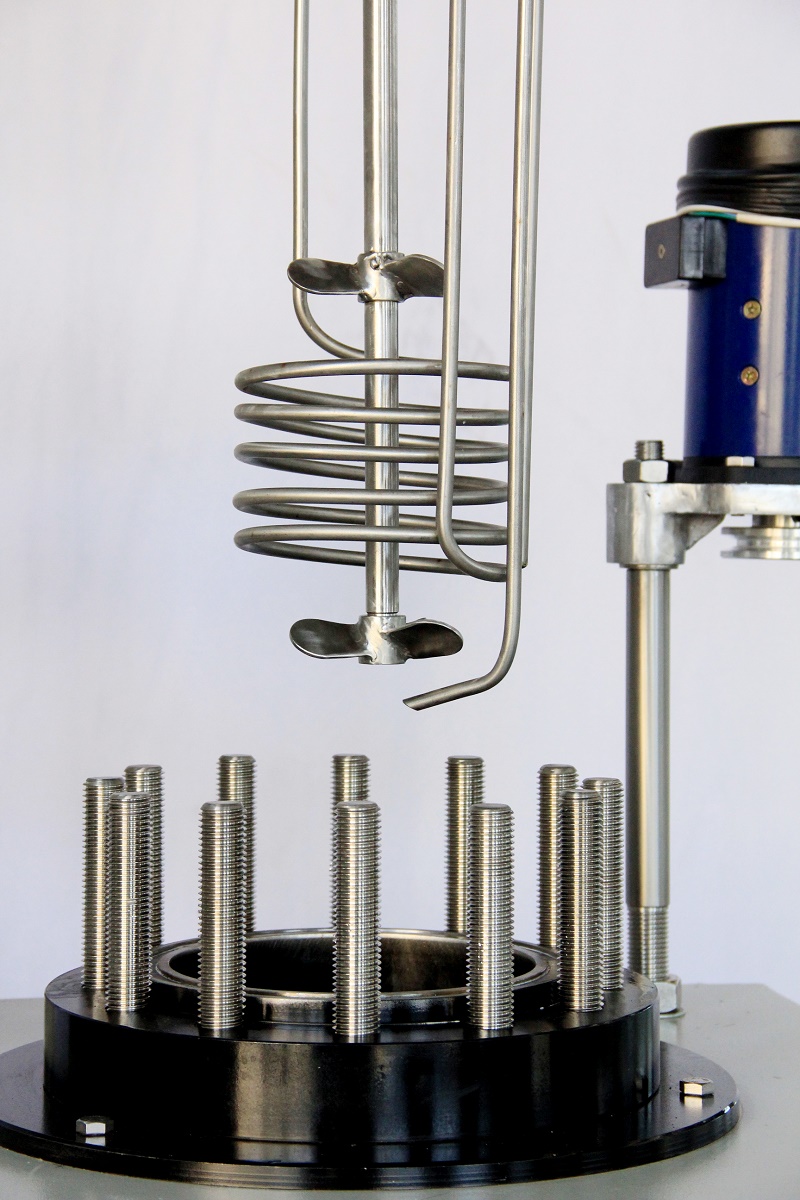

● Internal cooling coils, dip tube, temperature tube, etc.

● Bottom port: Drain valve / Ball valve;

● Heating method: Electric heating/ Jacket heating

● Shaft seal: Magnetic coupling drive

● Impeller: Paddle, propeller, anchor, helix impeller, etc.

● Controller: Temperature, pressure display and control. Stirring speed control.

Standard specfications

GSH lifting reactor standard specification table.

| Model No. | GSH-5 | GSH-10 | GSH-20 | GSH-30 | GSH-40 | GSH-50 |

| Nominal Capacity | 5liters | 10liters | 20liters | 30liters | 40liters | 50liters |

| Max Working Pressure | Standard 100bar; Max pressure up to 250bar | |||||

| Working Temperature | Standard 350°C;Up to 500°C | |||||

| Stirring Speed | 0-750rpm | 0-500rpm | ||||

| Motor Power | 600W | 600W | 1.1kW | 1.5kW | 1.5kW | 3KW |

| Heating Power | 4kW | 9kW | 9kW | 12kW | 12kW | 15kW |

| Closure | Flange bolts closure/ Clamp closure | |||||

Lifting & lowering | Manual crain lifting/ Electric crain lifting | |||||

| Material | SS304,SS316 or other alloys(Titanium, hastelloy, Inconel, Nickel, etc) | |||||

| Heating Method | Electric heating or Jacket heating | |||||

| Cooling | Internal spiral coils(Optional) | |||||

| Charging Method | Up discharge by pressure or discharge by bottom valve | |||||

| Impeller (Optional) | Propeller, paddle type, turbine, anchor type, gas induction, helix type, etc. | |||||

| Control panel | Temp.display and control, accuracy+ 1℃, Stirring speed display & control Touch screen program control(Optional) | |||||

| Standard fittings | Pressure Gage, Thermocouple, Central stirring port Liquid inlet/ Sampling port with needle valve & dip tube and gas inlet with needle valve Safety Rupture Disc: Internal cooling Coil(Optional); Solid feeding plug(Optional) | |||||

Product images

Customized Specifications

If there has special process requires,HXHCEM will also customize for you!

Pls list your basis process parameters like follows:

1. Reactor volume

2. Operating Temperature

3. Operating Pressure

4. Reactor Material / contacting components material

5. Agitator type, and the Mixing Speed, motor power request?

6. With heating device or not.

7. Internal cooling coil or not, exchange area?

8. Lifting device or not?

9. Your other requests

......Contact us

We like to help you to accomplish your plans.