Amination reactors

Amination reactors; Catalytic Reductive Reactors; High pressure animation autoclaves; Catalytic reductive pressure reactors; Stirred pressure autoclaves; Amination autoclaves Applications: Applied catalysis; Fine chemicals; Biological catalysis; Fuel cells

- HXCHEM

- CHINA

- 40 days after payment

- 5 SETs/MONTH

Details

Amination Reactors

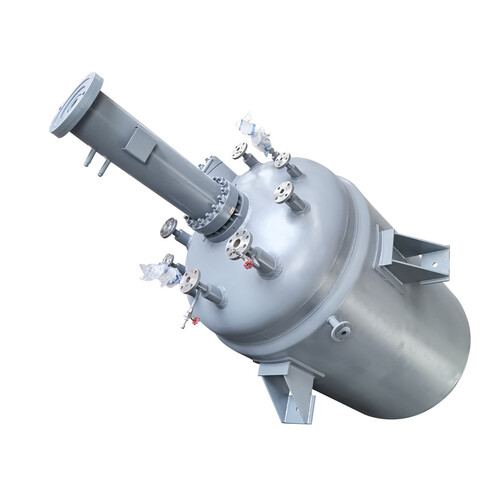

Gas induction impellers/ Magnetic driven/ Catalytic Reductive Amination Reactors

Catalytic reductive amination of aldehydes and ketones with nitro compounds is a promising methodology for an efficient and green synthesis of secondary and tertiary amines. To date, numerous catalytic hydrogenation and transfer hydrogenation processes have been designed employing both noble and non-noble metal catalysts!

Name: 1000L high pressure animation reactors

Total volume: 1000liters, 2000litres; 5000litres, 10m3, 20m3

Design pressure: 10bar.. up to 120bar;

Design temperature: Up to 300℃;

Jacket type: Oil/ Steam, Full jacket or limpet coil type;

Wetted material:SS304, SS316, hastelloy C22, hastelloy C276 solid or cladding;

Shaft seal: Mechanical or magnetic seal optional;

Certificate: GB; ASME U stamp; ISO certified; PED;

KEY FEATURES

Vessel with jacket or half pipe coils

High GAS hold up & gas-liquid interfacial area;

Recirculation of the GAS;

Uniform suspention of solid catalyst;

No leakage magnetic coupling drive agitator

Internall cooling/heating coils, dip tube, baffles.

Safety valve optional.

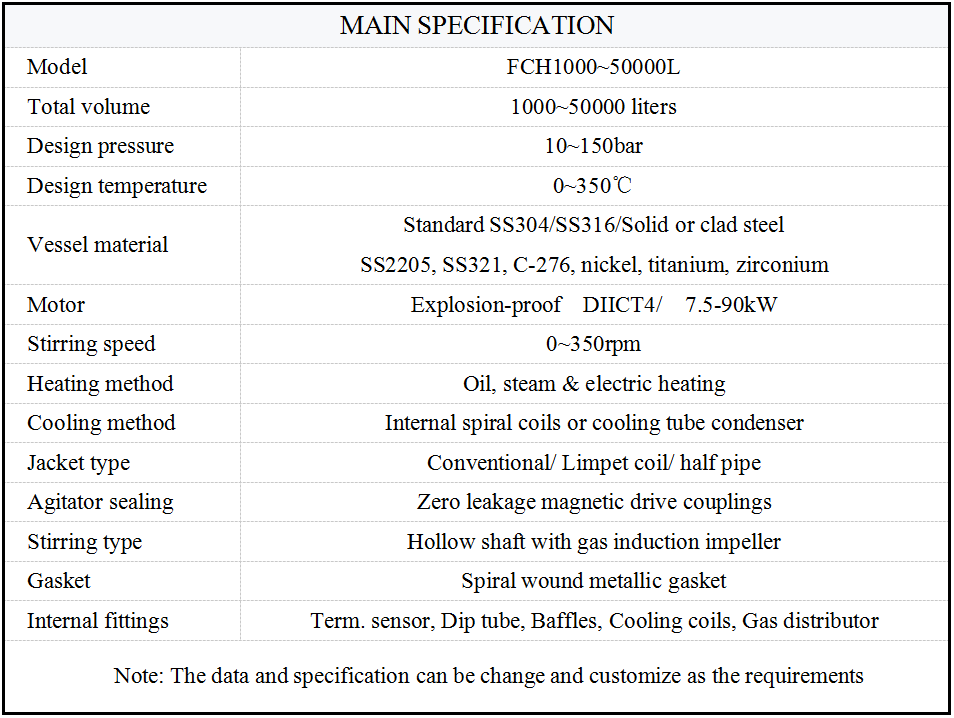

Specifcication