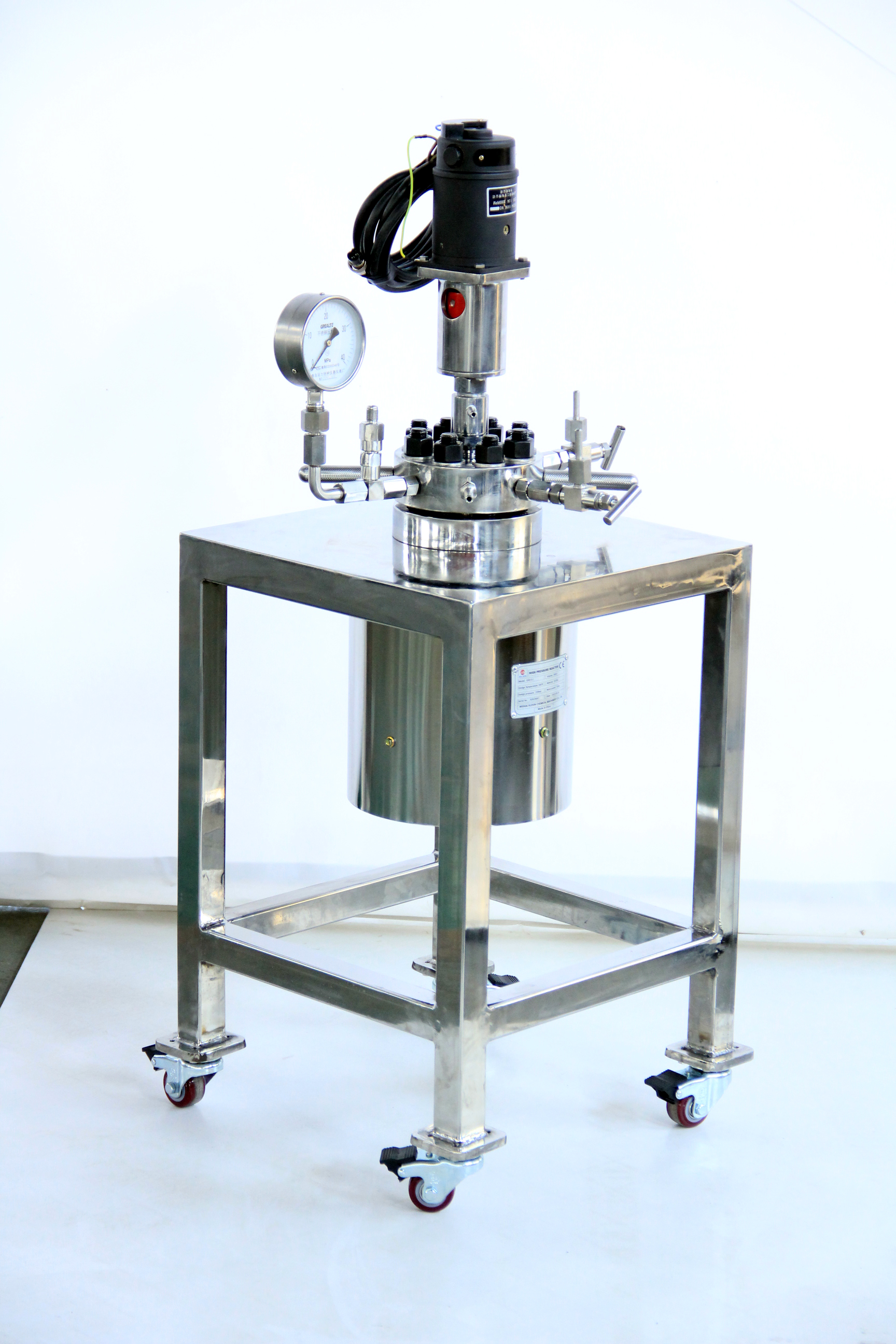

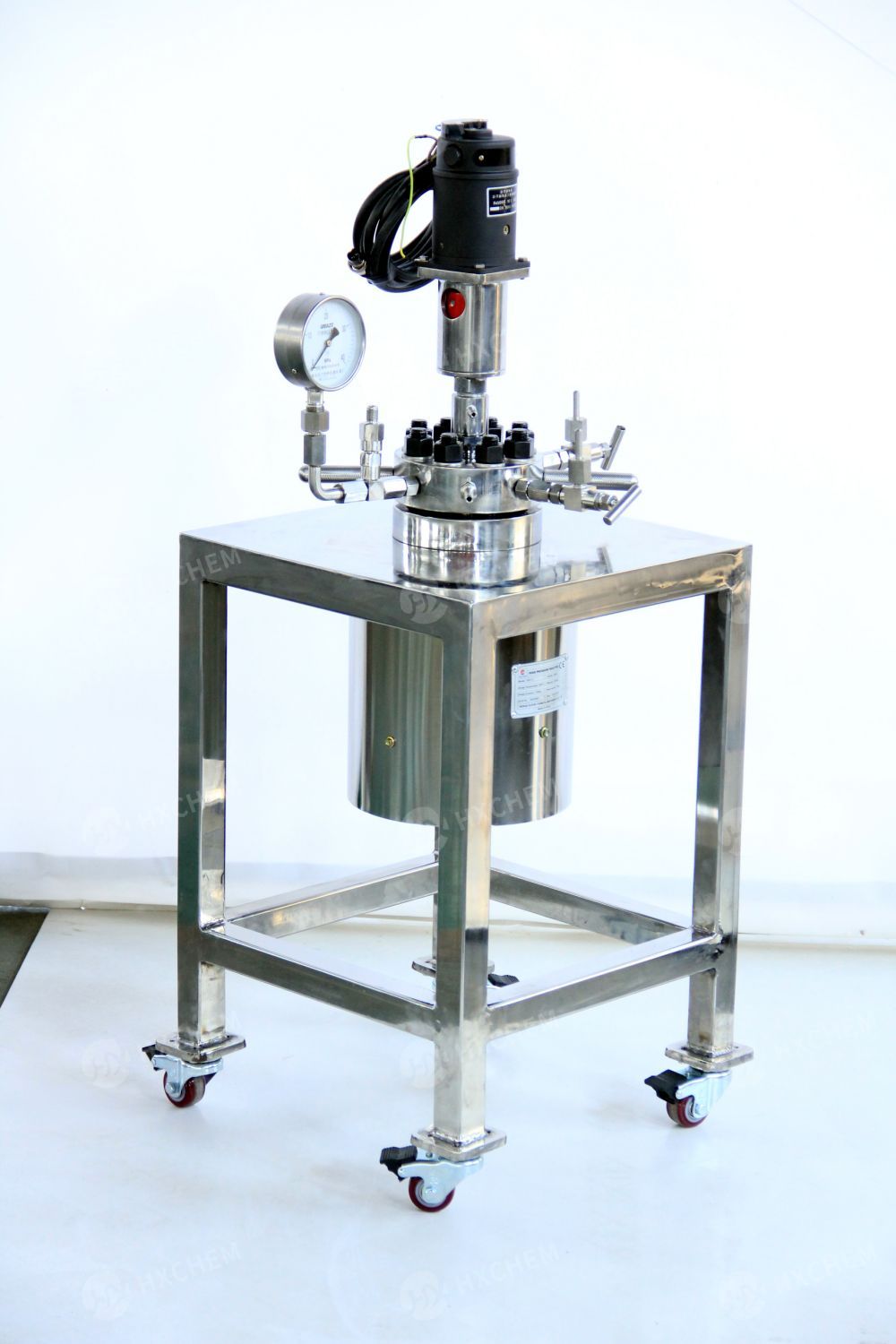

Floor stand lab high pressure reactors

lab high pressure reactors; Lab stirred pressure reactors; Floor stand pressure reactors; lab pressure reactor; Lab stirred autoclaves Flat cover lid: Fixed Closure type: Flange type with bolts closure Shaft seal: Direct driven magnetic coupling drive Reactor vessel: Fixed lab scale reactor Heating method: Electric heating/ Jacket heating. Cooling method: Internal spiral cooling. Control: PID temperature control.

- HXCHEM

- weihai

- 1 month

Details

Direct driven lab stirred pressure reactors

100ml-5liters pressure reactor

Product Introduction

Reactor volume: 100ml- 5liters

Pressure: -1 (FV) to +200 bar

Temperature: 20 °C to +350 °C

Material: Stainless steel 304/316, Hastelloy C276, Titanium

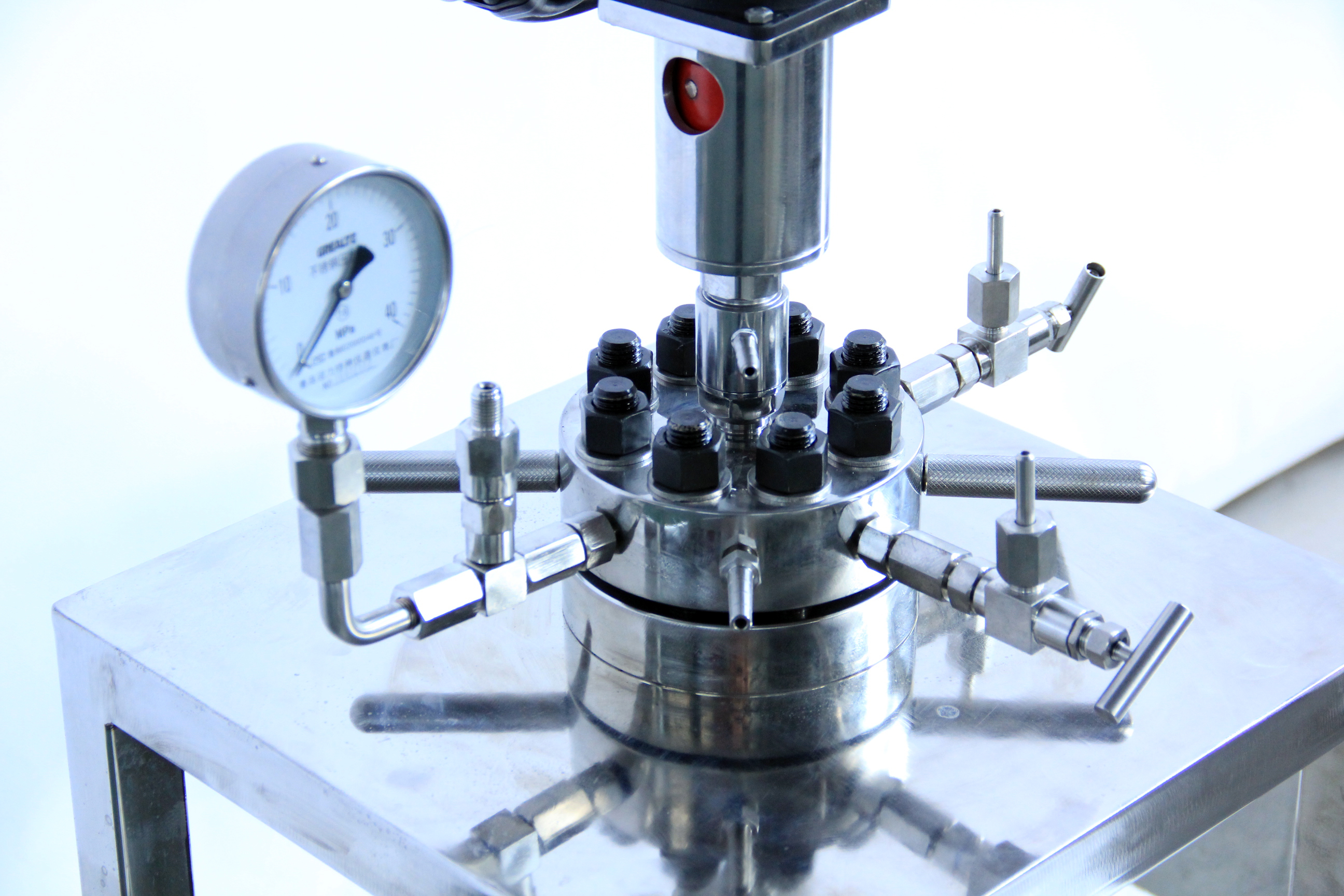

Features: Direct driven magnetic coupling drive agitator;

Other materials, pressures & temperatures are available.

Floor standard pressure reactors; Stirred pressure autoclaves, Lab batch reactor; lab scale reactor; Labraotry stirred autocalves; lab high pressure reactors; Lab stirred pressure reactors; Floor stand pressure reactors; lab pressure reactor; Lab stirred autoclaves

Features

Flat cover lid: Fixed

Closure type: Flange type with bolts closure

Shaft seal: Direct driven magnetic coupling drive

Reactor vessel: Fixed

Heating method: Electric heating/ Jacket heating.

Cooling method: Internal spiral cooling.

Control: PID temperature control.

100ml; 220bar; 350C; SS316l; Magnetic stirred lab pressure autoclave reactors.

Standard specfications

GSH model laboratory pressure reactor standard specification as fellow:

| Model No. | GSH-0.1 | GSH-0.25 | GSH-0.5 | GSH-1 | GSH-2 | GSH-5 |

| Nominal Capacity | 100ml | 250ml | 500ml | 1liters | 2liters | 5liters |

| Max Working Pressure | Standard 100bar;Max pressure up to 350bar | |||||

| Working Temperature | Standard 350°C;Up to 500°C | |||||

| Stirring Speed | 0-1500rpm | |||||

| Motor Power | 150W | 150W | 150W | 0.2KW | 0.2KW | 0.6KW |

| Heating Power | 1KW | 1KW | 1KW | 2KW | 2KW | 4KW |

| Material | SS304,SS316 or other alloys(Titanium, hastelloy, Inconel, Nickel, etc) | |||||

| Heating Method | Standard Electric heating ( Thermal oil recycling, far infrared heating optional ) | |||||

| Cooling | Internal spiral coils(optional) | |||||

| Charging Method | Up discharge by pressure or discharge by bottom valve | |||||

| Stirring type | Propeller, paddle type, turbine, anchor type, gas induction, helix type, etc. | |||||

| Control panel | Temp.display and control, accuracy+ 1℃, Stirring speed display & control Touch screen program control(Optional) | |||||

| Standard fittings | Pressure Gage, Thermocouple, Central stirring port Liquid inlet/ Sampling port with needle valve & dip tube and gas inlet with needle valve Safety Rupture Disc: Internal cooling Coil(Optional); Solid feeding plug(Optional) | |||||

Hydrogenation, Catalyst Screening / Testing; Polymerization, Styrene Butadiene; Alkoxylation, Distillation, Ethoxylation; Hydrocracking, Dehydrogenation, Oxidation

Other related product