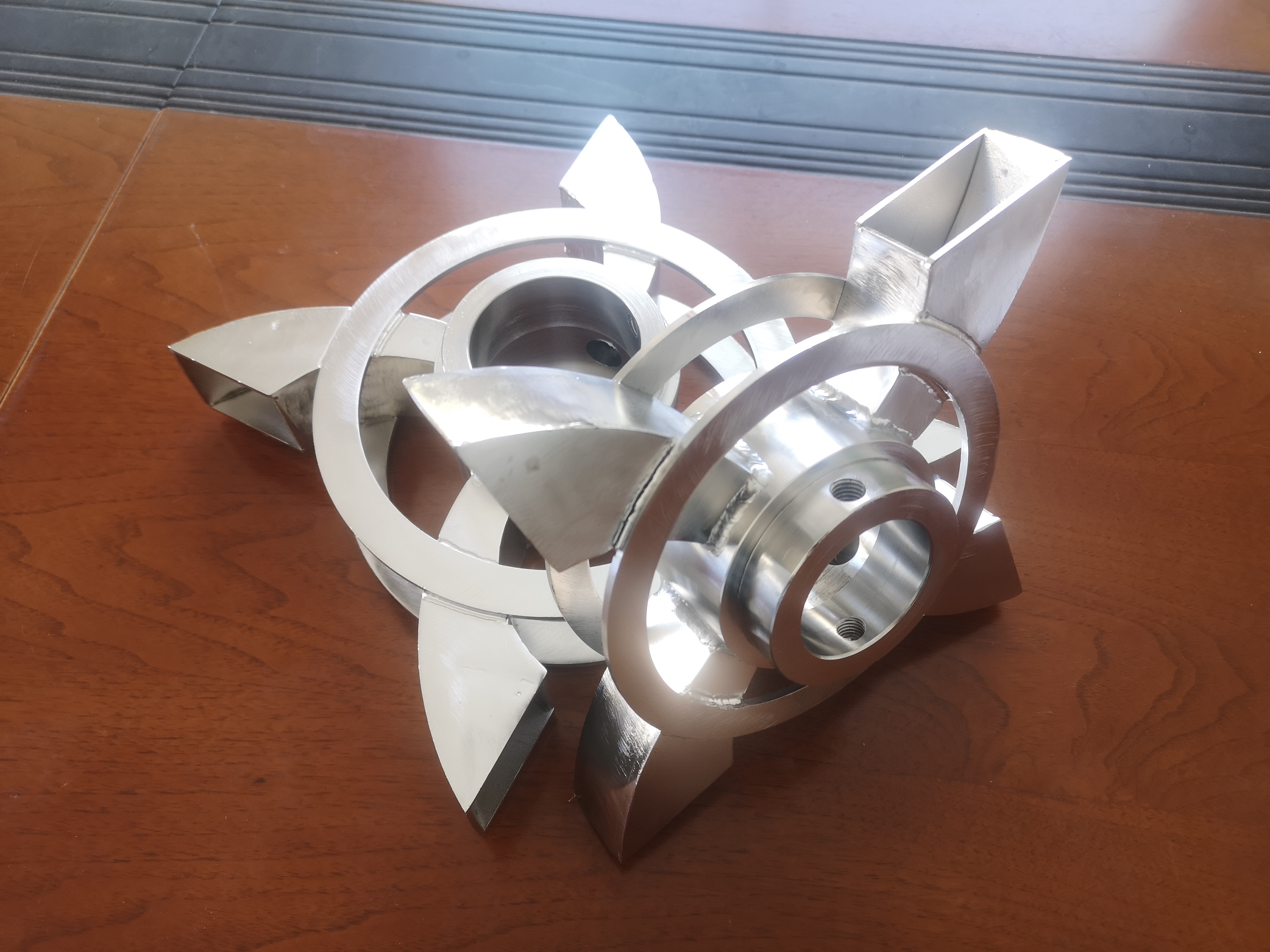

Hollow gas inducing impeller for hydrogenation

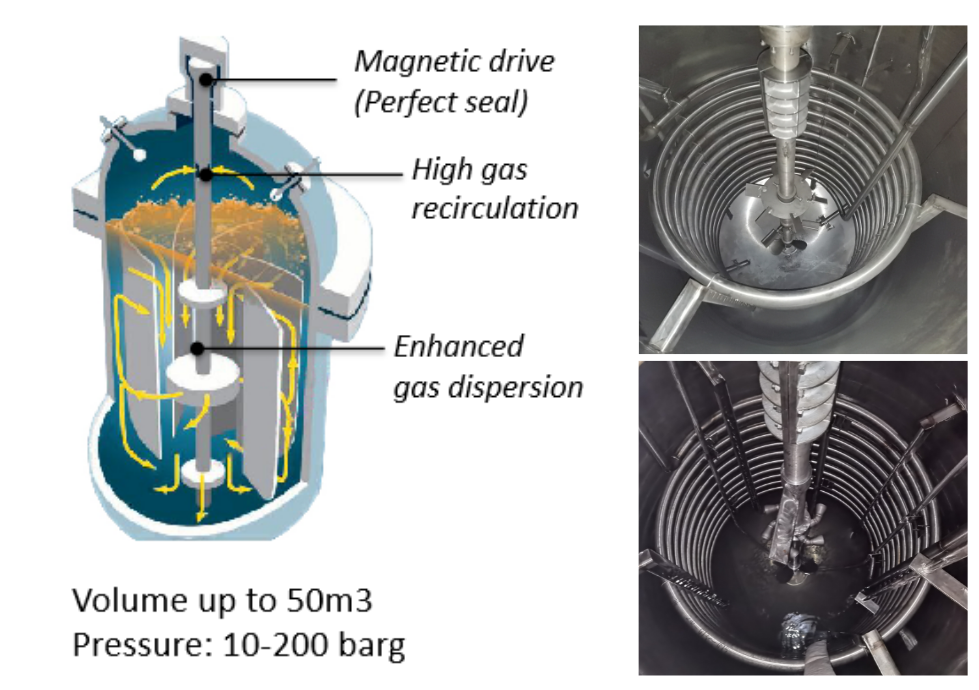

High mass transfer Hollow gas inducing impeller for hydrogenationammination, chlorination, bromination & other gas-liquid reactions) Radial low; Gas-liquid mixing flow impelller; Self- inducing impeller. Complete gas consumption; High productivity; Uniform suspension of the catalyst;Gas-liquid reaction. A fine dispersion of the gas and therefore a large interfacial area.

- HXCHEM

- China

- 5 days after payment

- 100 sets/month

Details

Hollow gas inducing impeller for hydrogenation

Introduction

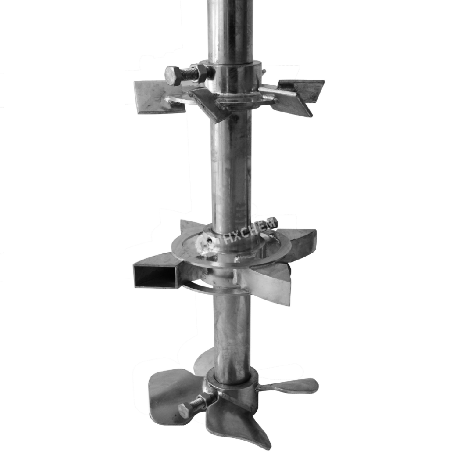

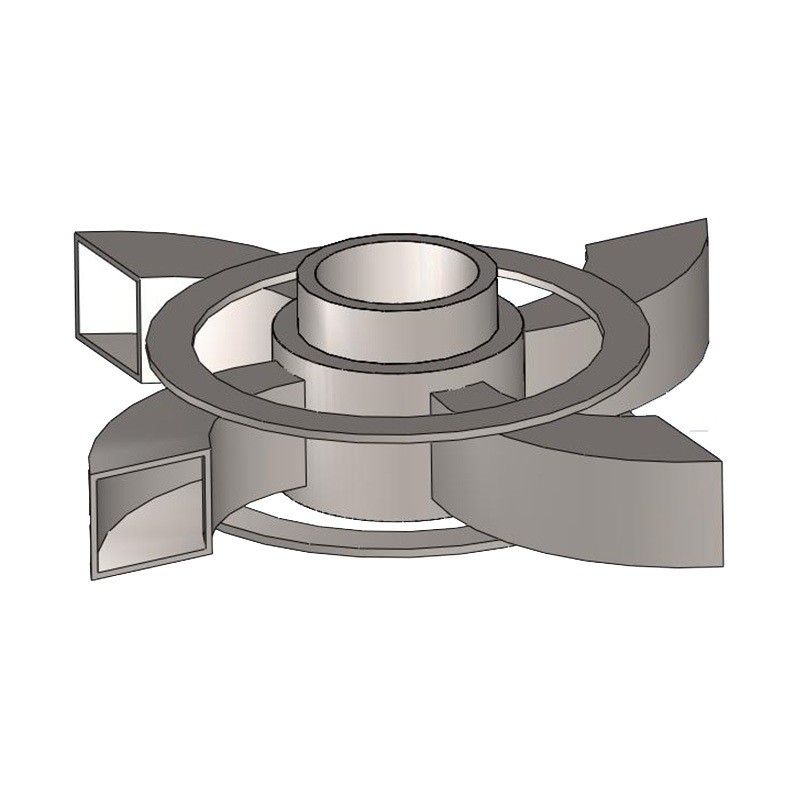

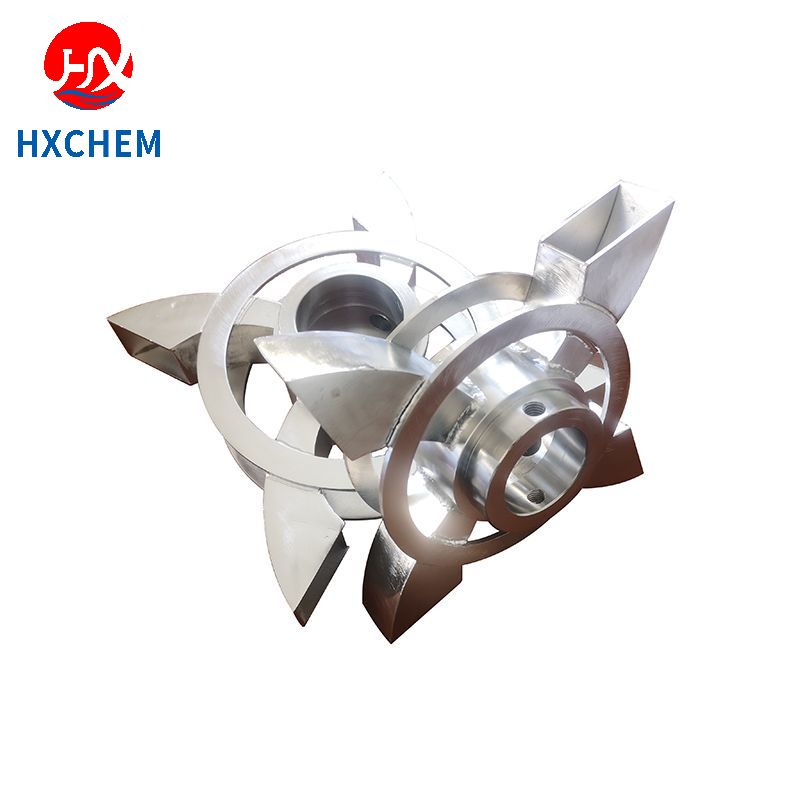

This series is a kind of gas self-inducing blade. Gas is inducing through the hollow shaft and then leads to the lower end of the shaft through a gas channel of special shape.

The vacuum pressure generated by blade rotation makes the gas inhaled from the upper opening port of the shaft, imported into the liquid, and dispersed evenly in the liquid.

The gas flow inhaled and dispersed by the self-inducing blade with high pumping efficiency strength the contact area of the liquid and gas, thus achieving higher mass transfer.

The traditional self-aspiring impeller will limite the gas handling capacity because it is easy flooding. This series impeller designed by HXHCEM avoids this problem, thus it can process higher gas flow than the traditional blade.

Hollow gas inducing impeller for hydrogenation ; Gas induction impeller; Gas inducing impeller; Hollow self-inducing impeller; Gas induction agitators; Gas entrainment impellers; Gas-liquid dispersion impeller; Gas self inducing impeller; Self-aspirating impeller; Combined gassing impeller; Gas inducing agitator; hydrogenation impeller

Product Features

Radial low; Gas-liquid mixing flow impelller; Self- inducing hydrogenation impeller.

Complete gas consumption; High productivity; Uniform suspension of the catalyst;Gas-liquid reaction

A fine dispersion of the gas and therefore a large interfacial area.

Application: Hydrogenation; Chlorination; Oxidation; Acylation; Alkoxylation; Amination; Carboxylation.

Technical Requirements

Diameter of impeller: 30~2000 mm

Diameter of shaft: 10~300 mm

QTY of impeller: 4, 6, 8, 10..

Available material:CS, SS304, SS316, Titanium, Nickel, Hastelloy B/C, Monel, Zirconium, Inconel, Tantalum

Product Details

Quick Selection

| Type | Mixing speed | Application | Feature |

Marine propeller Broad blade Propeller | 100-500r/min | Low viscosity | Low shear, low energy consumption Strong circulation High-speed operation |

Paddle type

| 50-200r/min | Medium viscosity | Close to the tank wall Heavy duty, slow operation High energy consumption Inefficient mixing |

Turbine type

| 50-350 r/min | Low viscosity Medium viscosity | Medium shear and cyclic Medium speed operation Suitable for medium equipment |

| Disk turbine (Flat blade, pinched blade, curved blade, ) | 100-350 r/min | Low viscosity Medium viscosity | Strong shear, gas dispersion Medium speed operation High energy consumption |

Frame type Anchor type Helical Blade | 20-150 r/min | High viscosity | Low shear and speed Strong cycle ability High energy consumption |

Self inducing type | 200-500 r/min | Liquid-gas mixing | Strong self-inducing capacity High gas consumption High speed operation |