Large torque magnetic drive couplings stirrer

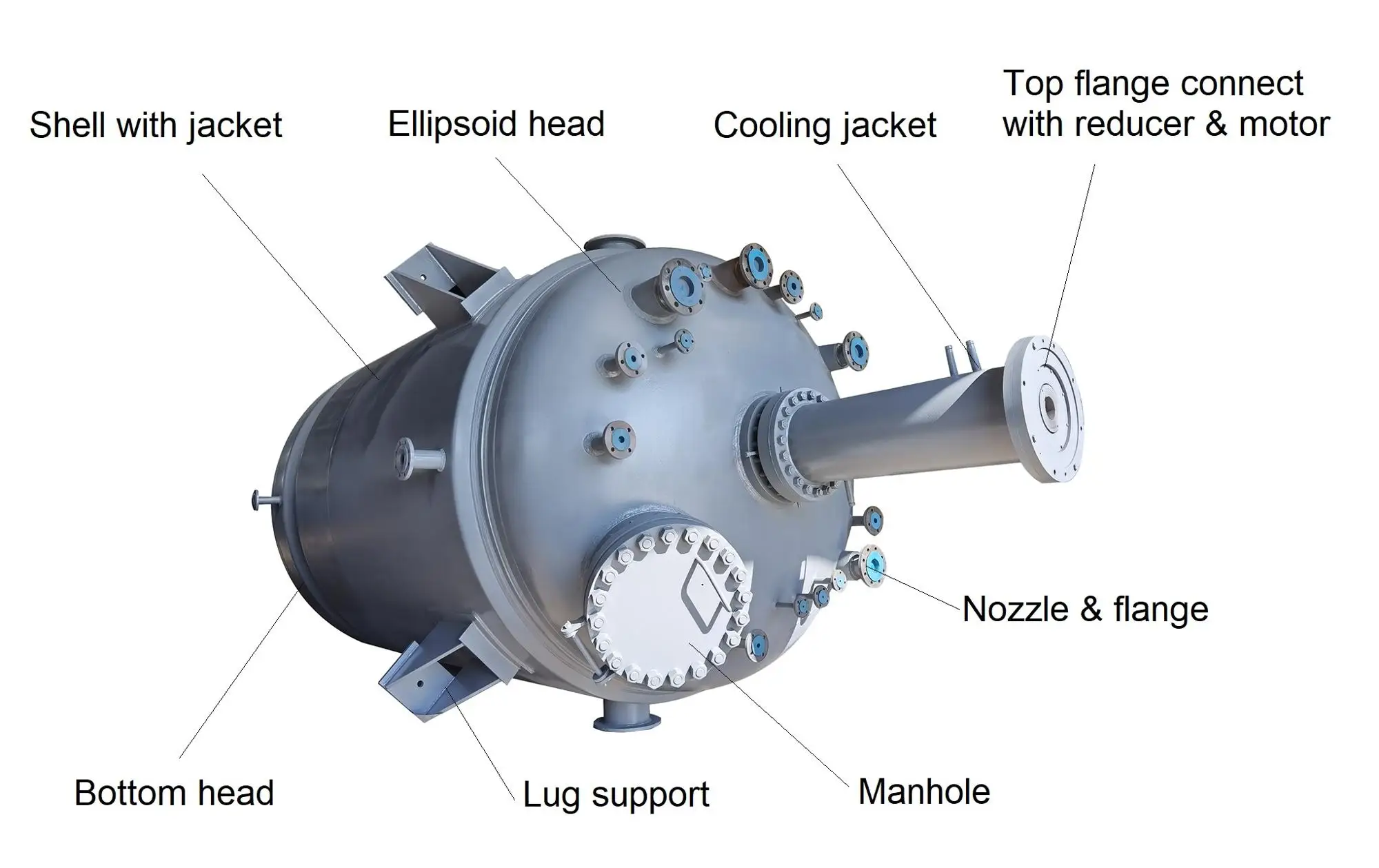

MI series high torque industrial magnetic coupling agitators is match for FCH high pressure reactor, which is widely used in the industrial scale high pressure high temperature reaction. Pressure Reactions, such as Hydrogenation, Amination, etc. * Reactions with noxious gases. * Manufacture of potent pharmaceuticals, such as hormones, oncology products, etc. * Any other reactions requiring complete containment, and where there are zero leakage requirements. Magnetic stirrer; Magnetic stirrer drives; magnetic drive couplings; magnetic coupling stirrer

- HXCHEM

- China

- 30 days after payment

- 100 sets/month

Details

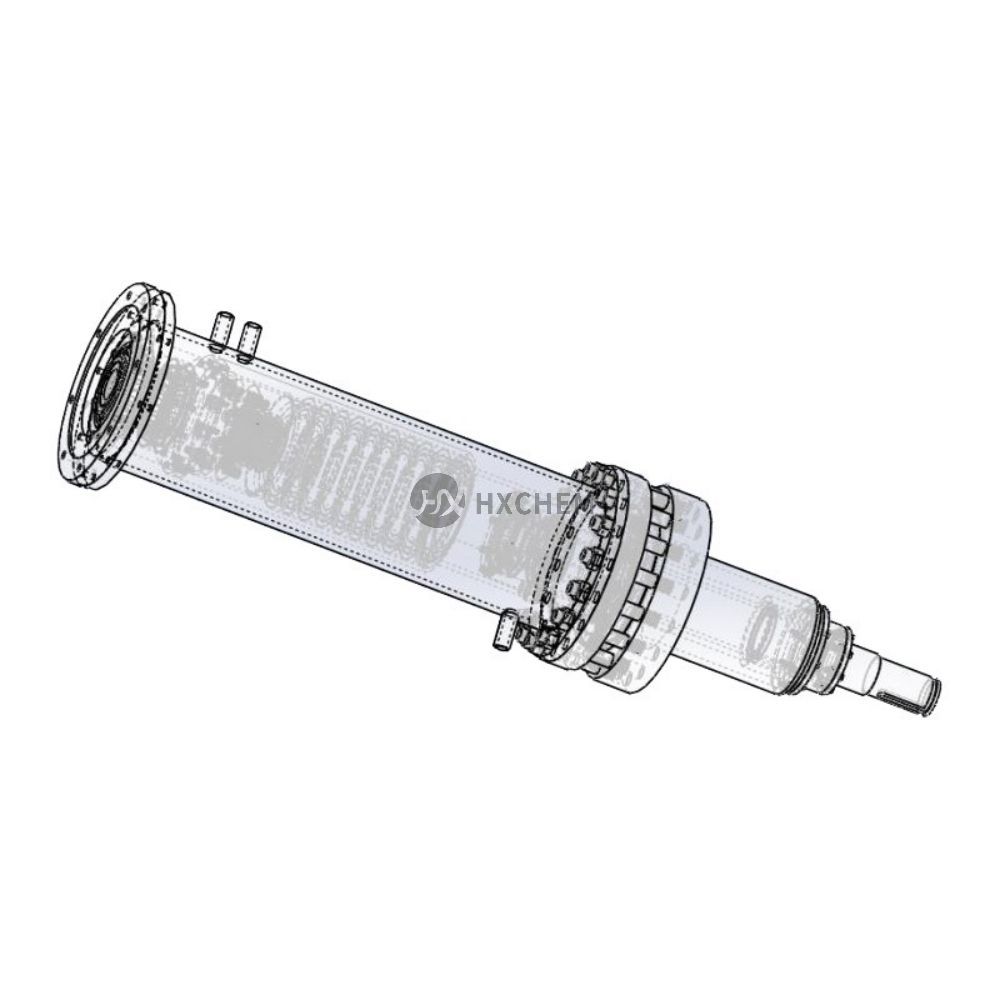

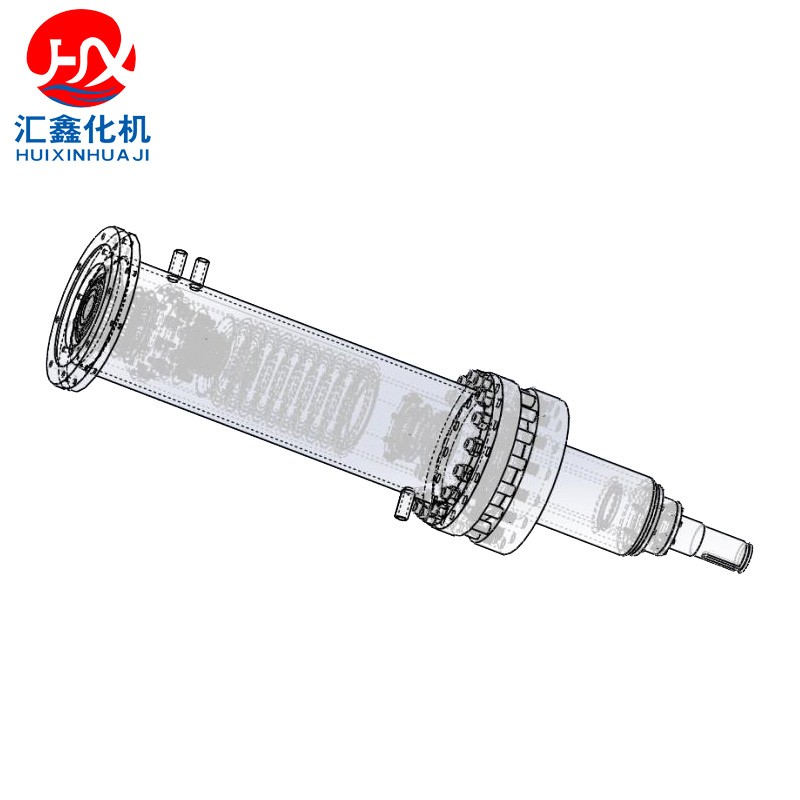

Large torque magnetic drive couplings stirrer

MI series Large torque magnetic drive couplings stirrer is match for 1000litres - 50000litres high pressure hydrogenation reactor/ Pressure kettles, which is widely used in the industrial scale high pressure high temperature reaction. In applications with critical, highly toxic or aggressive media, hermetically sealed drives are inevitable. The permanent magnetic couplings offer a reliable alternative to conventional dynamic seals due to their contactless and leakage-free torque transmission in agitators and mixers.

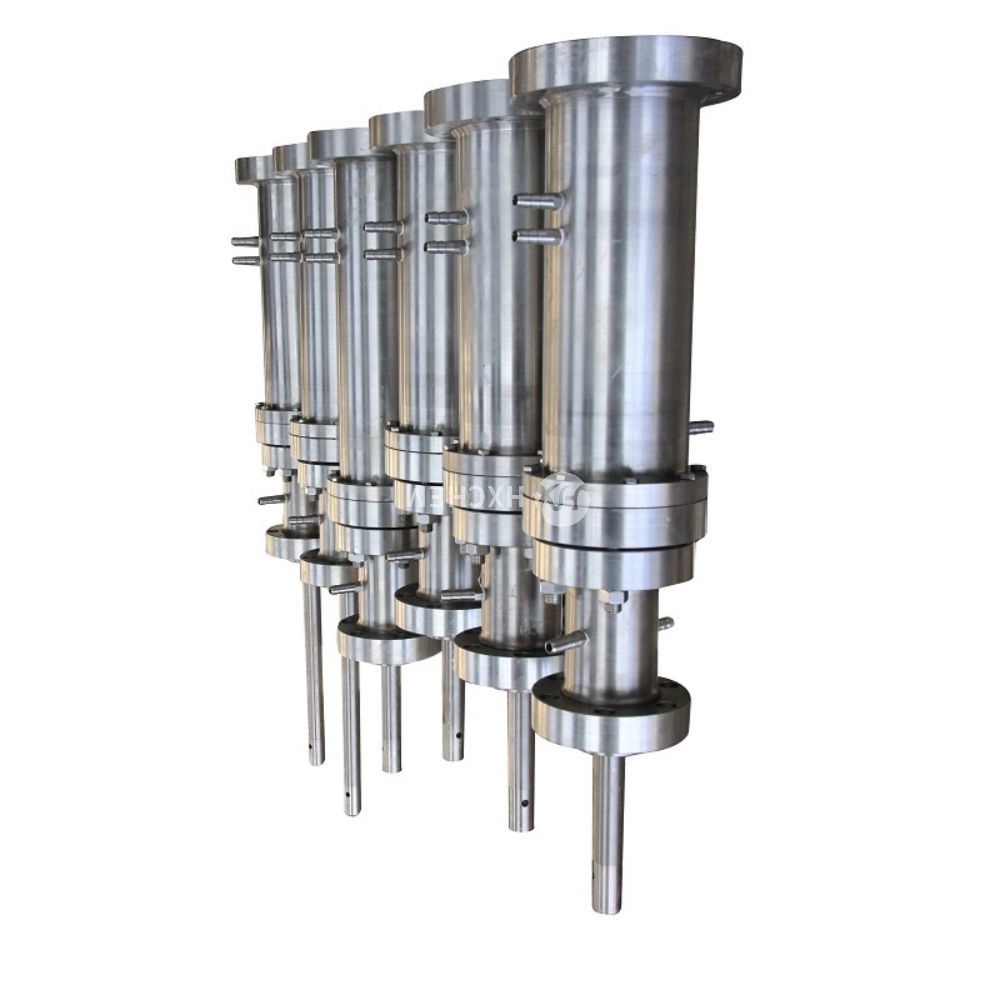

HXCHEM customize various large torque magnetic drive couplings stirrer/ magnetic couplings/ magnetic stirrer; magnetic stirrer drives; magnetic drive couplings; magnetic coupling stirrermagnetic agitator / industrial stirrer / agitator manufacturer / chemical agitator / paddle agitator / mixing propellers agitator / propeller agitator

Product Features

* Suitable for industrial reactor with volume 1000L~50m3

* Full vaccum to 200 bar available; Cooling jacket design for high temperature application.

* Materials of SS316, Hastelloy C, inconel, monel, titanium etc. for resistance to various chemicals.

* MI series (DIRECT DRIVE): Magnetic couplings drive connect with motor directly.

* Customized flange closure.

* Low to high torque magnetic couplings: static seal with zero leakage.

Details Images

Working principle

A Magnetic seal comprises of a sealed chamber, which contains a rotating Inner Shaft, is embedded with powerful Inner Magnets. This inner shaft is supported on Upper and Lower Bearings. These are special Bearings, capable of withstanding harsh environments present inside the Reactor. A special barrier filter prevents dust from entering the Bearing Area. The output shaft of Motor/Gearbox assembly is locked on to an Outer Rotor, which is fitted with an Outer Magnet Assembly. When the Motor is switched on, the Outer Rotor Rotates, and magnetic flux causes the inner shaft to rotate synchronously with the Outer Rotor.

Technical Requirements

| Type | MI type |

| For volumes | 1000L - 50m3 |

| Motor power | 7.5 - 110 kW |

| Torque range | 400 - 7000 N-m |

| Stirrer speed | 0 ~ 500 rpm |

| Pressure range | Full vacuum / 200 bar |

| Temperature range | - 40°C to + 350°C |

| Materials | CS, SS, Hastelloy C276 , Titanium, Nickel, Zirconium, others. |

Applications

* Reactions with noxious gases.

* Manufacture of potent pharmaceuticals, such as hormones, oncology products, etc.

* Any other reactions requiring complete containment, and where there are zero leakage requirements.

Industrial magnetic agitator images