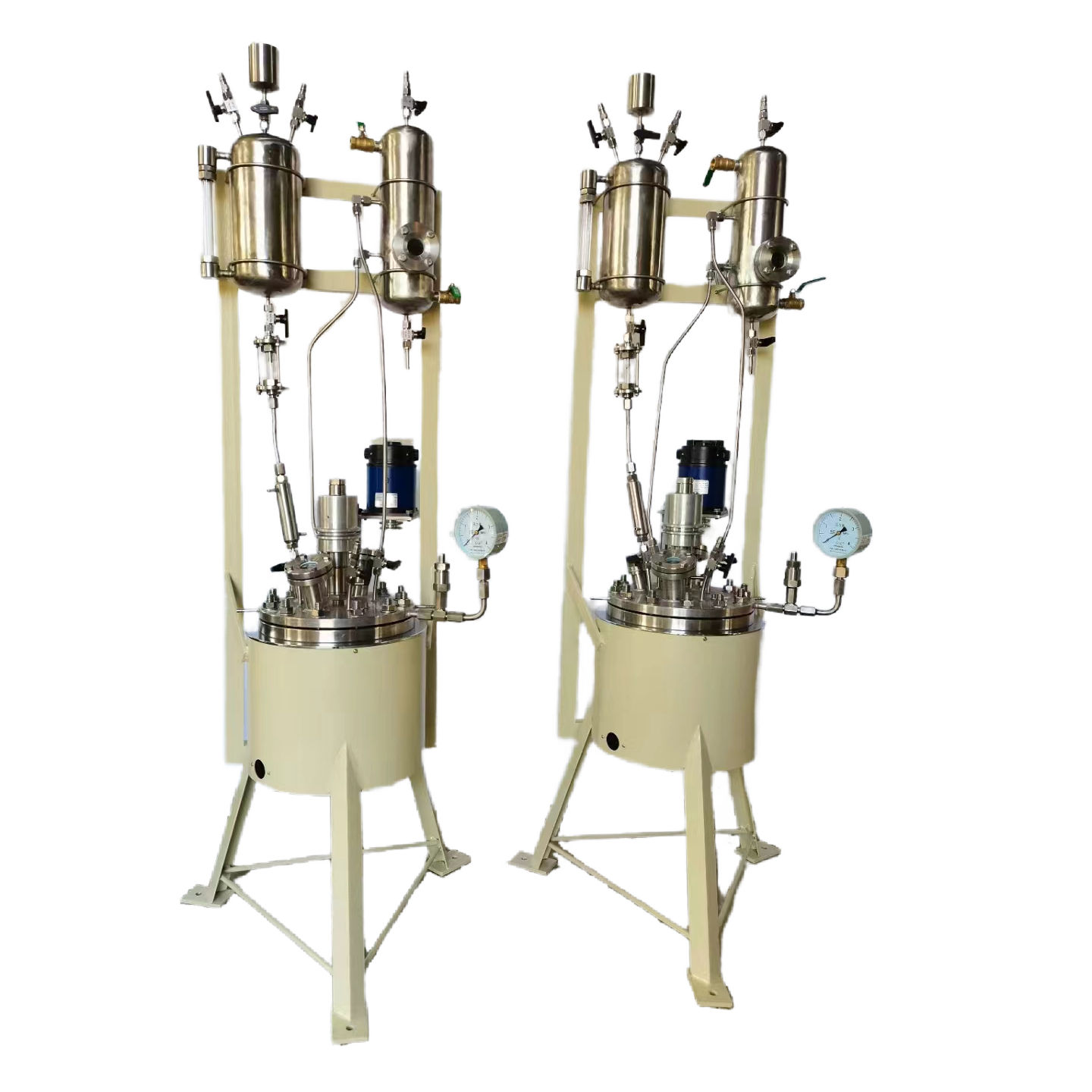

Small pressure reactor with continuous feeding and collection

*Reactor volume: 1.0 liter *Euipped with feeding tank & collecting tank; *Lab pressure reactor/ 1liters pressure reactor/ Pressure reactor with feeding unit/ Pressure reactor with cycling devices/ Hydrogenation reactor/ Small pressure reactor/ stirred pressure autoclave/ Lab continuous hydrogenation reactor/ stirred pressure autoclave

- HXCHEM

- CHINA

- 20 DAYS

- 10 SETs/MONTH

Details

Laboratory pressure reactor

Contiuous feeding and collection under pressure

Laboratory stirred autolcave

with magnetic coupling agitator

Reactor volume: 1.0 liter, 2.0liter

Pressure: -1 (FV) to +100 bar

Temperature: 20 °C to +300 °C

Material: Stainless steel 304/316, Hastelloy C276, Titanium

Features: Euipped with constant pressure dosing tank,

cycling pipeline, receiver, collecting tank;

Features

● Flat cover lid: Fixed

● Closure type: Flange type with bolts closure

● Shaft seal: Magnetic coupling drive

● Reactor vessel: Fixed

● Other devices: Euipped with constant pressure dosing tank, cycling pipeline, receiver, collecting tank.

● Control: PID temperature control.

Specification

GSH model laboratory pressure reactor standard specification as fellow:

| Model No. | GSH-0.1 | GSH-0.25 | GSH-0.5 | GSH-1 | GSH-2 | GSH-5 |

| Nominal Capacity | 100ml | 250ml | 500ml | 1liters | 2liters | 5liters |

| Max Working Pressure | Standard 100bar;Max pressure up to 350bar | |||||

| Working Temperature | Standard 350°C;Up to 500°C | |||||

| Stirring Speed | 0-1500rpm | |||||

| Motor Power | 150W | 150W | 150W | 0.2KW | 0.2KW | 0.6KW |

| Heating Power | 1KW | 1KW | 1KW | 2KW | 2KW | 4KW |

| Material | SS304,SS316 or other alloys(Titanium, hastelloy, Inconel, Nickel, etc) | |||||

| Heating Method | Standard Electric heating ( Thermal oil recycling, far infrared heating optional ) | |||||

| Cooling | Internal spiral coils(optional) | |||||

| Charging Method | Up discharge by pressure or discharge by bottom valve | |||||

| Stirring type | Propeller, paddle type, turbine, anchor type, gas induction, helix type, etc. | |||||

| Control panel | Temp.display and control, accuracy+ 1℃, Stirring speed display & control Touch screen program control(Optional) | |||||

| Standard fittings | Pressure Gage, Thermocouple, Central stirring port Liquid inlet/ Sampling port with needle valve & dip tube and gas inlet with needle valve Safety Rupture Disc: Internal cooling Coil(Optional); Solid feeding plug(Optional) | |||||

Product Details

They are available up to a working pressure of 100 bar and a maximum temperature up to 350 °C. Available materials: stainless steel, Hastelloy, Titanium. Various heating/cooling systems, magnetic stirrers or magnetically coupled overhead stirrers, as well as a wide variety of gas and liquid supplies are available. They can be designed as single and parallel reactor plants. In addition to the standard configurations, you can also have plants specially tailored to your requirements.