Double jacket mixing tank

We supply all types and sizes of mixing tank/ Double jacket mixing tank/Stainless steel mixing tank/Liquid mixing tank/ Three layer mixing tank to various processing industries. Some of these processing industries include food, beverage, dairy, chemical, pharmaceutical, nutraceutical, fruit & vegetable, sauce and dressing, cosmetics, food protein, lotions, candy and many other processing industries.

- HXCHEM

- China

- 30 days after payment

- 40 sets/month

Details

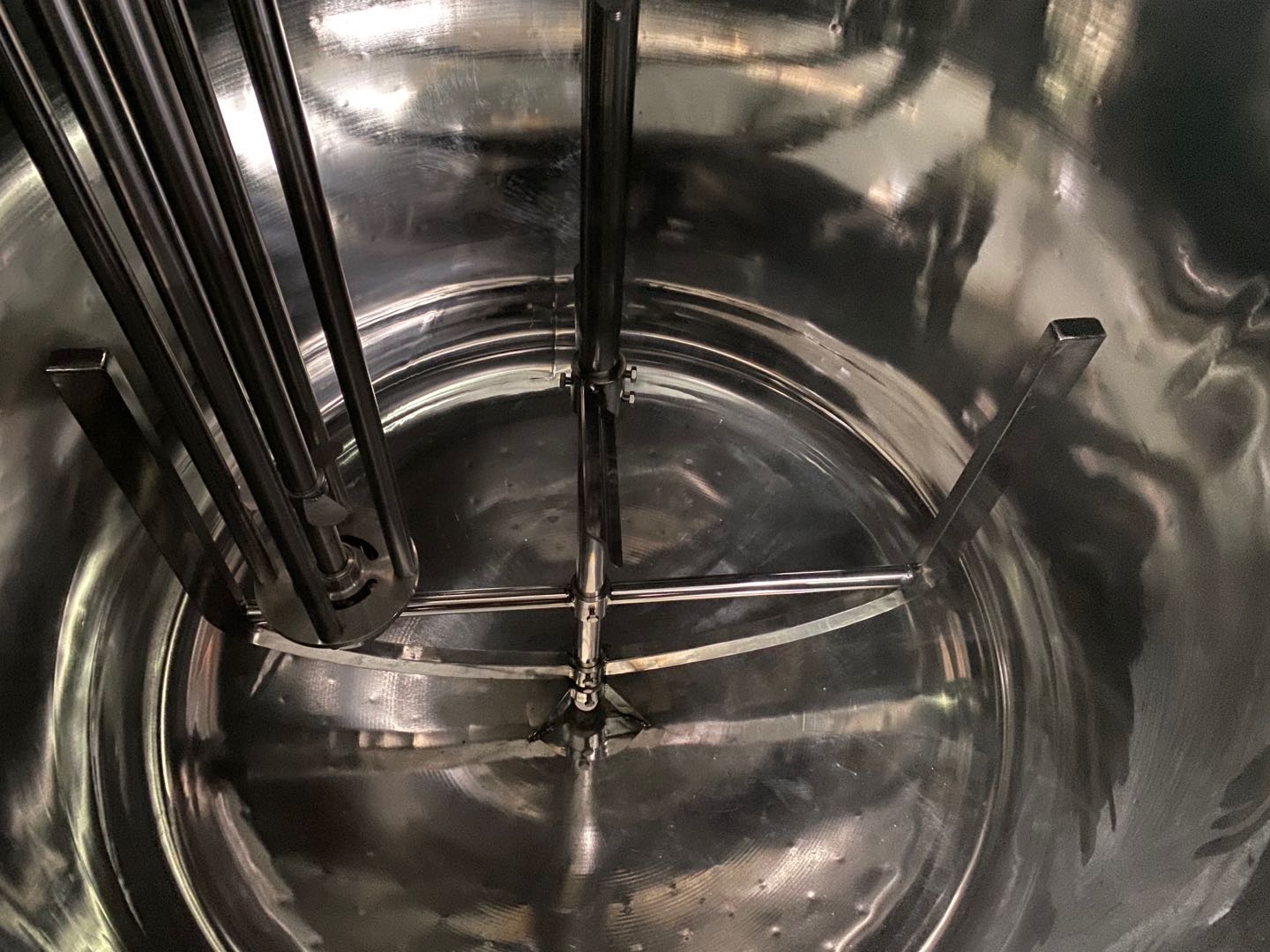

Vertical double jacket stainless steel mixing tank

Chemical heated jacket mixing tank,it's widely applied in the beverage, food, dairy, pharmaceutical, chemical and process industries used as blending tank, buffer tank, melting tank, high shear mixing tank and emulsifying tank, which cleanable to sanitary standards .

SPECIFICATION

| SPECIFICATION OF MIXING TANK | |

Material | SS304 or SS316 |

Working Capacity | 50L to 20000L, even more large. |

| Operate pressure | Atmosphere |

Layer | Single/ Double(heating)/ Three layers(Insulation); |

| Thickness | 2mm- 12mm |

Heating or cooling | (1) Electric heating (2) Steam heating (3) Hot water or oil circulated |

Top | Dome or conical top or flat |

Bottom | Dome or conical top or flat |

| Impeller type | Paddle /propeller / anchor / magnetic stirrer / high shear homogenizer mixer |

| Polishing | Mirror polish inside and outside |

Component (Optional) | (1) Manhole (2) Spraying ball (3) Lifting lugs on the top ( selectable) (4) Outlet or inlet valve,all other type valve ( selectable ) (5) Feet: adjustable feet ( selectable ) (6) Ladder ( selectable ) (7) Thermometer , Liquid level meter ( selectable ) (8) The pressure gauge ( selectable ) |