Laboratory Loop pressure reactors

HXCHEM customize laboratory Loop pressure reactors;Lab loop pressure reactors; Laboratory Loop pressure reactors; Continuous hydrogenation reactor; Loop hydrogenation reactor; Catalyst fixed bed reactor

- HXCHEM

- China

- 20 days after payment

- 15 sets/month

Details

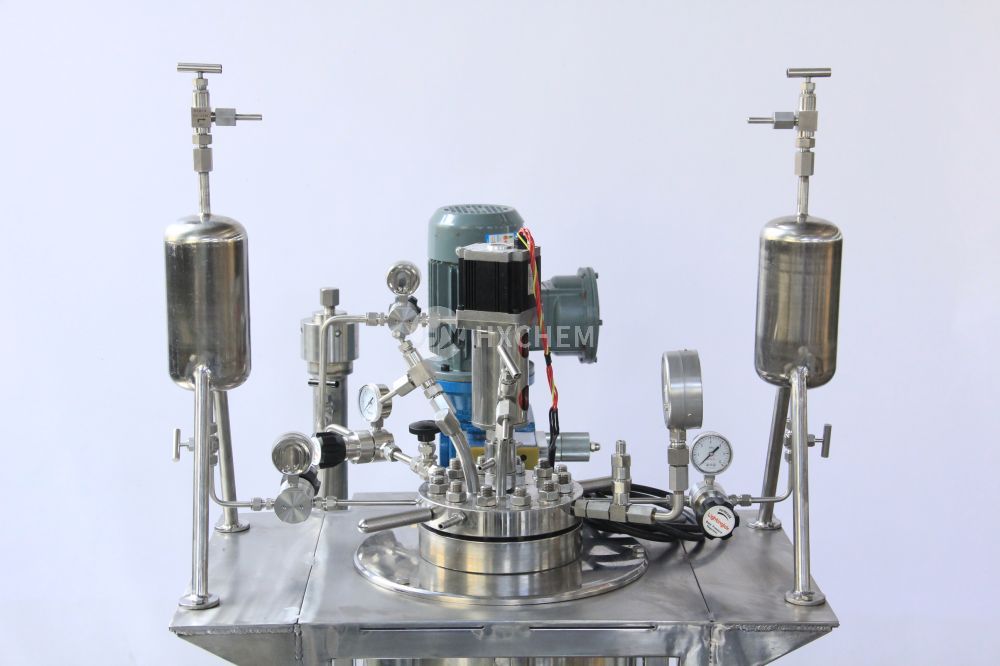

Laboratory Loop pressure reactors

Hydrogenation reactors-continuous process

Laboratory stirred pressure reactor/hydrogenation reactor/ Loop pressure reactor with a magnetic coupled stirred agitator, provide a high efficiency gas liquid mixing. The loop pressure system design helping increase a further gas liquid mixing, which including high pressure pump, catalyst fixed bed reactor, filter, liquid feeding tank, cycling pipeline system, back pressure valve.

FEATURES

Hydrogenation volme:2liters

Design pressure: 50bar

Design temperature: 100C

Material: SS316L

Heating method: Oil jacket heating

Impeller type: Hollow gas induction impellers

Catylist fixed bed reactor: Tube type; Filter/0.5um, back pressure valve, etc.

Plunger metering pump, 10h/h

Two solvents feeding tank with back pressure valve.

APPLICATION

Most of these gas induction reactors and hydrogenation reactors find extensive applications for various high-pressure gas–liquid reactions where gas dispersion & mass transfer at high pressure form the key design element. These gas-liquid reactors are used in pilot facility & manufacturing of fine & speciality chemicals, bulk drug (API) pharmaceuticals, dyes, intermediates, paints, oils, agrochemical, petrochemicals, oil & gas, defence organisations etc. to carry out various high pressure high temperature liquid-liquid, gas-liquid and gas-liquid-solid reactions like alkylation, amination, acetylation, acylation, bromination, carboxylation, catalytic reduction, chlorination, dehydrogenation, esterification, ethoxylation, halogenation, hydrogenation, methylation, nitration, oxidation, ozonisation, polymerization, sulphonation etc.