Large capacity wiped film distillation system

Thin film evaporation are mostly used for first-stage degassing to prevent explosive boiling when entering the main evaporator, especially for the high light component ratio conditions. The HXCHEM thin Film Evaporators normally operate within a pressure range of 1 mbar to 100 mbar.

- HXCHEM

- China

- 20 days after payment

- 15 sets/month

Details

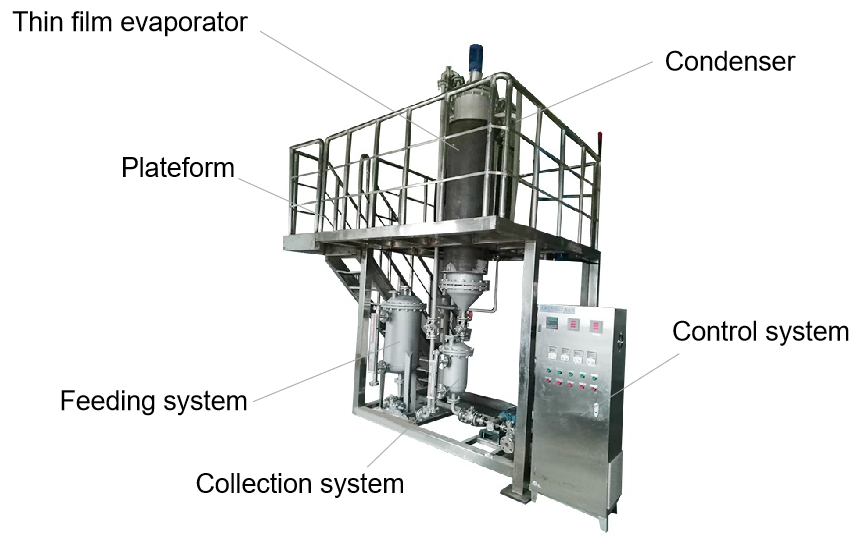

Single Stage Thin Film Distillation System For Degassing

Introduction

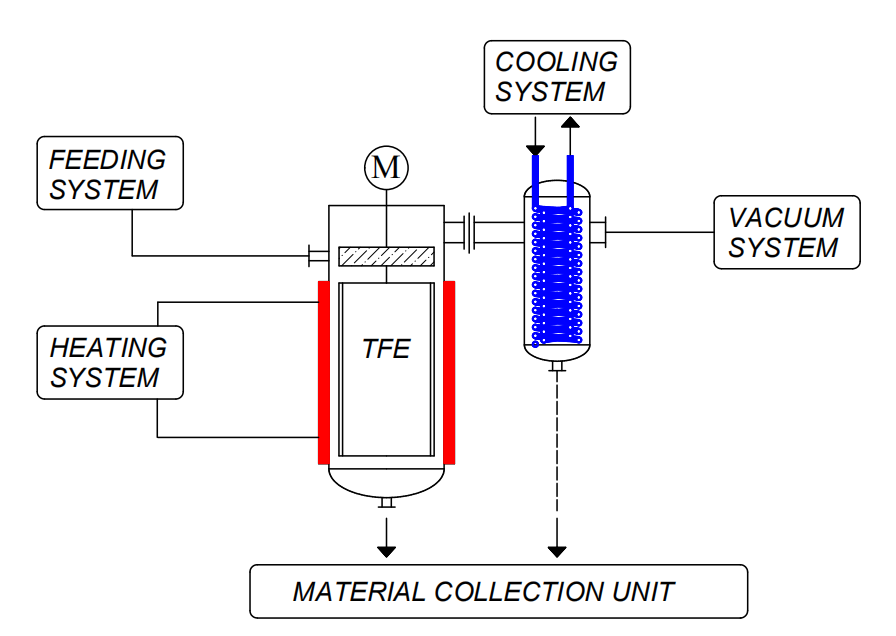

Single-stage thin film distillation is mostly used for solvent recycling, but in multi-stage distillation, thin film evaporators are mostly used for first-stage degassing to prevent explosive boiling when entering the main evaporator, especially for the high light component ratio conditions. In a thin film evaporator(TFE), a rotating wiper system distributes the crude product to a film on the inner surface of a heated surface. The wiping system speeds up the evaporation process by keeping the product film turbulent so that the heat transfer and mass transfer are optimized. The vapour are condensed on the external condenser and the residue are discharged from the bottom of the evaporator.

Product Features

High heat transfer efficiency, fast evaporation speed and short material residence time.

Heating area:0.05m2~40m2 available.

High evaporation rates and high yield

Turnkey solution available

Batch or continuous process available; Low fouling on evaporator wall

Combination with additional evaporation stages (Colume, Degassing stage, etc)

TFE constructed of stainless steel or other special materials and alloys

Different wiper systems are selected depending on the product properties

Basic Configuration(TFD)

Feeding system(including pre-heating and degassing stage)

Thin film evaporator(TFE)

External condenser and cold trap

Collection systems for distillate and residue

Heating and cooling systems

Vacuum system

Technical Requirements

Model | TFD-0.1 | TFD-0.3 | TFD-0.5 | TFD-1 | TFD-2 | TFD-4 | TFD-6 |

Effective heating area (m2) | 0.1 | 0.3 | 0.5 | 1 | 2 | 4 | 6 |

Condenser area (m2) | 0.25 | 0.6 | 1.5 | 2.5 | 3.5 | 7.5 | 8 |

Inner diameter (mm) | 85 | 100 | 207 | 313 | 350 | 400 | 500 |

Feeding Rate (kg/h) | 3~15 | 5~35 | 20~70 | 50~120 | 100~250 | 200~350 | 350~600 |

Height (m) | 2.3 | 2.6 | 3.2 | 4.5 | 5 | 7 | 8 |

Vacuum Level (mbar) | Low to 1 mbar(100Pa) | ||||||

Working Temp. (℃) | Up to 300℃ | ||||||

Feeding Mode | Pressure differential valve;High-precision gear pump;Peristaltic pump | ||||||

Collection Mode | Glass collection flask;Stainless steel tank;High-precision gear pump | ||||||

Can be customized according to customer's requirements. | |||||||

Note: Data in the table are standard specification. The specific size is based on the customer's demand.

Product Drawing

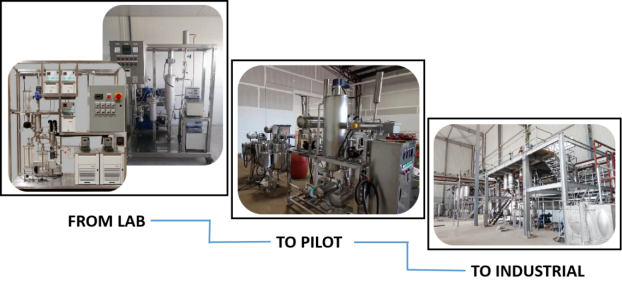

Turnkey Solutions

HXCHEM can provide customized services according to customer requirements, such as multilevel systems or other special requirements to meet different productivity needs, finally achieve the turnkey solution provided.

Feasibility analysis Process analysis.

Preliminary overall layout Detailed design.

Manufacturing and transportation Installation and testing.

Training and after sales service.

Application

The wiped film distillation system/ wiped film distillation equipment/ thin film distillation system/ Industrial wiped film distillation/ thin film evaporator plant is mainly used in the pre-treatment process of food and health products, also widely used in solvent removal and distillation separation in pharmaceutical, chemical industry and other industries.

Oil purification, concentration;Ethanol recovery;

Distillation, Separation, Concentration, Stripping, Deodorization, Degassing, Reaction

Heat sensitive, viscous, fouling and foaming products

Continuous processing