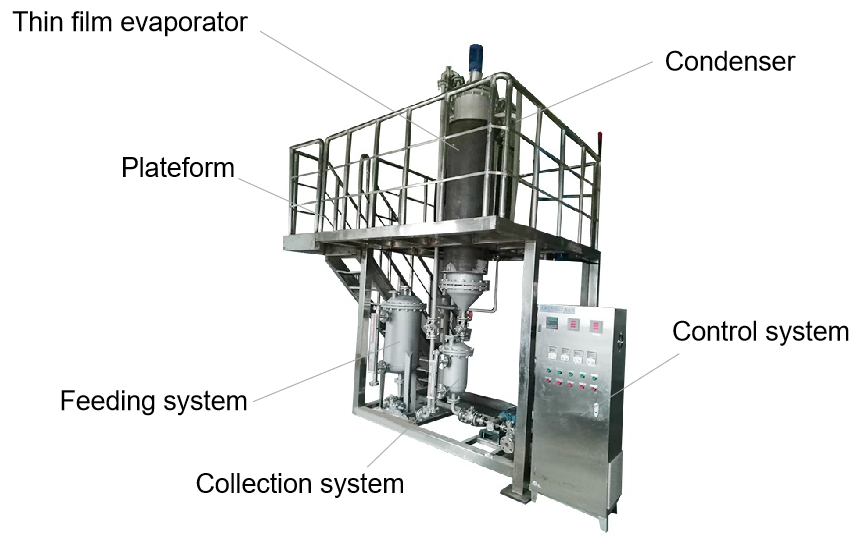

2m2 thin film distillation equipment

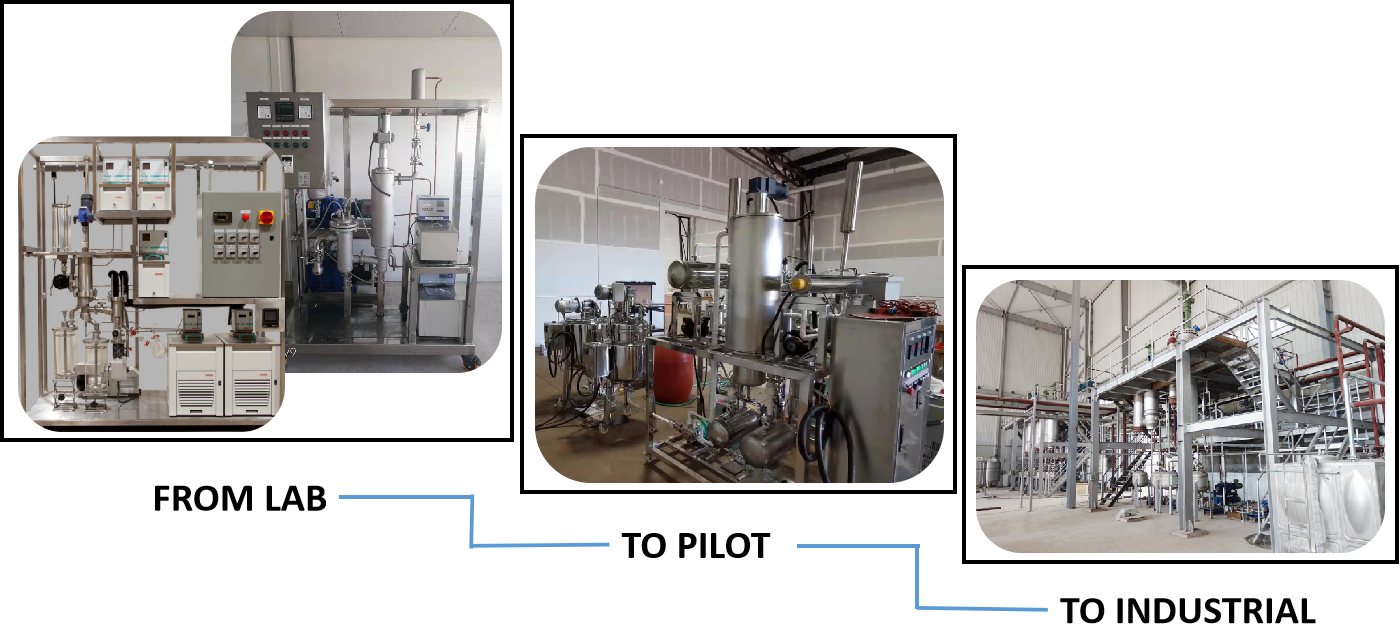

This is an efficient method for industrial cannabis to recycle ethanol solvents, which is also applicable to other recycling solvents. The HXCHEM thin Film Evaporators normally operate within a pressure range of 1 mbar to 100 mbar. By means of reduction of pressure and special design, the temperature and duration of thermal stress of a product can be reduced considerably and the quality is greatly improved.

- HXCHEM

- China

- 45 days after payment

- 15 sets/month

Details

2m2 thin film distillation equipment

Introduction

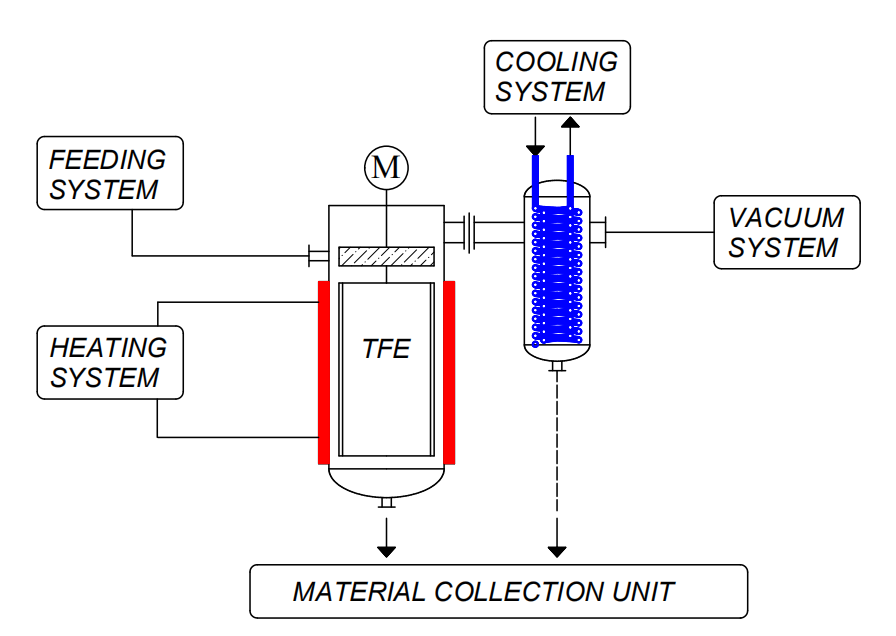

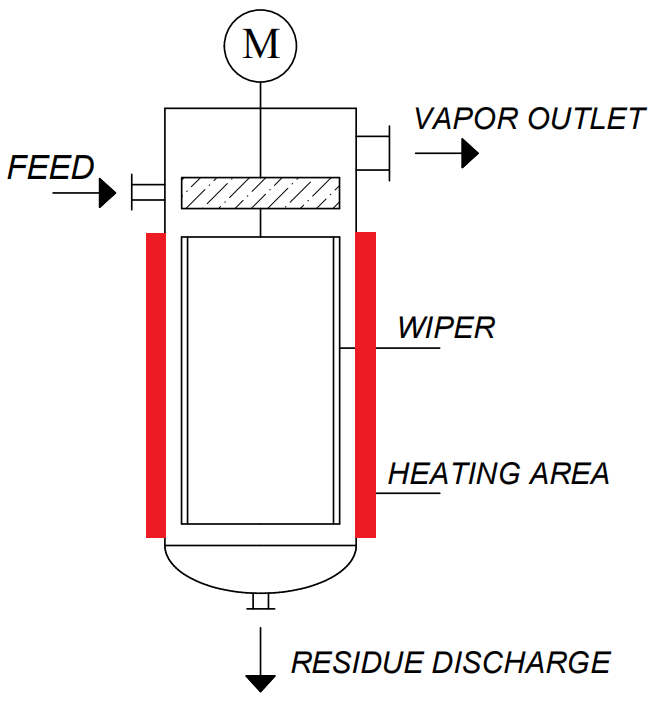

This is an efficient method for industrial cannabis to recycle ethanol solvents, which is also applicable to other recycling solvents. In a thin film evaporator(TFE), a rotating wiper system distributes the crude product to a film on the inner surface of a heated surface. The wiping system speeds up the evaporation process by keeping the product film turbulent so that the heat transfer and mass transfer are optimized. The vapour are condensed on the external condenser and the residue are discharged from the bottom of the evaporator.

Thin film distillation equipment; Thin film distillation; Wiped film distillation; thin film evaporator plant; wiped film distillation system; wiped film distillation unit; Thin film distillation system; Industrial thin film distillation.

Product Features

Heating area:0.05m2~2m2 available

Batch or Continuous distillation process available

The system including evaporator, external condenser, pump, chiller, heater, vacuum system, pipeline, etc.

Different wiper systems are selected depending on the product properties

Basic Configuration(TFD)

Feeding system(Including pre-heating and degassing stage)

Thin film evaporator(TFE)

External condenser and cold trap

Collection systems for distillate and residue

Heating and cooling systems

Vacuum system

Product Drawing