Product recommendation

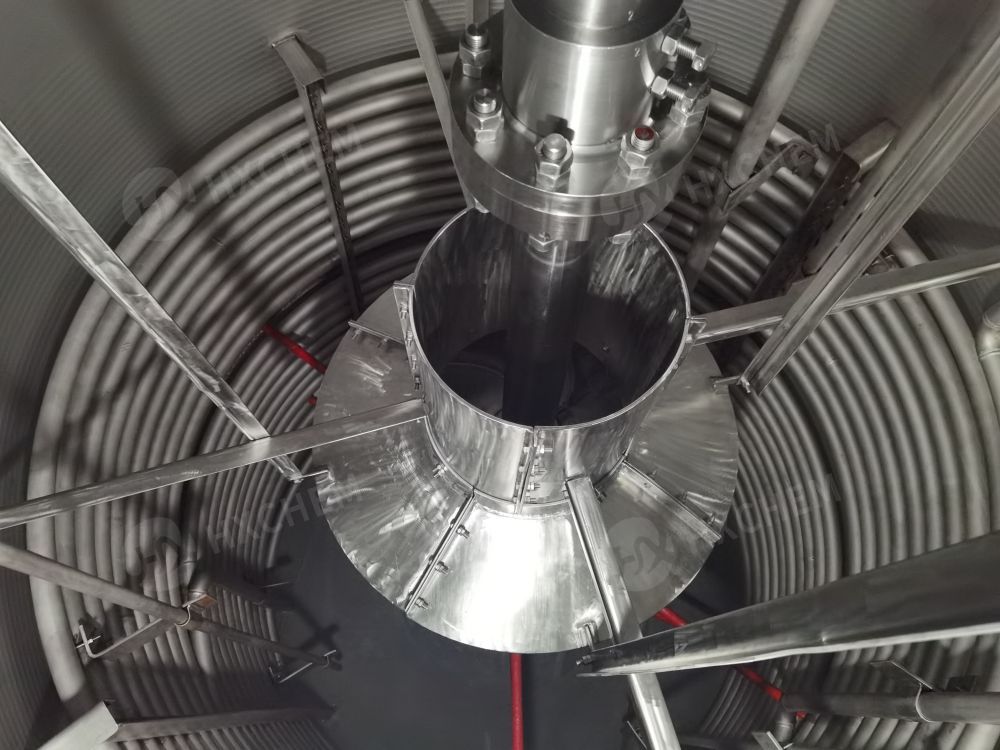

Explosion cladding pressure reactor vessels

HXCHEM provide customized cladding pressure reactor;Explosion cladding vessels;cladding pressure vessels;pressure reactor vessels;Explosion cladding reactors to chemicals, food, cosmetics, oil, phamacy industry, eviroment, etc.

Explosion clad can be a cost-effective solution when large diameter, vacuum, and heat transfer are required for Pressure Vessels, Columns, Heat Exchangers, and Piping. Explosion cladding is a process where solid metal plates of dissimilar metals are joined into a single plate having the same mechanical and corrosion resistant properties of the existing metal.

PROCESS

√ Base material is primarily carbon steel or stainless steel but can be any material. The base plate is designed per the specified pressure vessel design code to the design pressure and temperature requirement.

√ Clader material is selected to be the corrosion resistant barrier for the pressure vessel. This material is commonly:

Titanium/ Zirconium/ Hastelloy/ Nickel/ Inconel/ Monel/ Duplex Stainless Steel/ Austenitic Stainless Steel

√ Mating surfaces are ground clean

√ Assemble base plate / Alloy clader / Explosive

√ Explosion

√ Flattening

√ Testing / Inspection

HXCHEM specialize in custom engineered explosion clad Pressure Vessels, Reactors, Columns, and Piping for chemical process. Our specialty is working in corrosion-resistant alloys, including:

√ Titanium Explosion Clad (TA1, TA2, TA9, TA10)

√ Zirconium Explosion Clad

√ HASTELLOY Explosion Clad(Hastelloy C276, C22)

√ Inconel Explosion Clad (Inconel 625)

√ Nickel Explosion Clad (Ni6)

√ Duplex Stainless Steel Explosion Clad (2205, 2507)

√ Stainless Steel Explosion Clad (SUS304, SUS316, 910S, 310S)

√ SS321 Explosion Clad

.

HXCHEM can build pressure equipment based on numerous pressure vessel codes including ASME, PED/CE, and the Chinese GB Code.

Manufacturing capacities include diameters up to 4000mm and weights up to and exceeding 100 tons.

You’ll find HXCHEM chemical Pressure Vessels, Reactors, Storage tanks, Heat exchangers, Columns — wherever there is a corrosion problem to be solved.

Contact us by phone at (+86) 15666305701 or send us your questions via email at jerryliu@hxchem.net.cn.

Please visit product page for more information

-

Non Ferrous metal cladding equipment

HXCHEM manufactures heavy wall & non ferrous metal cladding equipment for high pressure and high temperature applications in the Chemical/Petrochemical and Oil & Gas industries. Process equipment properly fabricated from corrosion-resistant alloys can handle extremely corrosive applications. Corrosion-resistant alloys are a distinct category of metals and specialty alloys(Non ferrous metal equipment, Exotic metal equipment) including Titanium, Zirconium, Tantalum, Hastelloy, High Nickel Alloys, as well as the Duplex and Super Stainless Steels.

More