Nickel alloy cladded reactors

Nickel-6 reactor is resistant to reducing, oxidizing & neutral conditions and offers outstanding resistance to caustic alkalis in the high temperature. Nickel alloy cladded reactors | Nickel fusion reactor/ Nickel alloy reactors/ Nickel reactors/ Nickel alloy cladding reactors/ Nickel alloy pressure vessels/ Nickel alloy pressure reactors

- HXCHEM

- China

- 80 days after payment

- 5sets/ month

Details

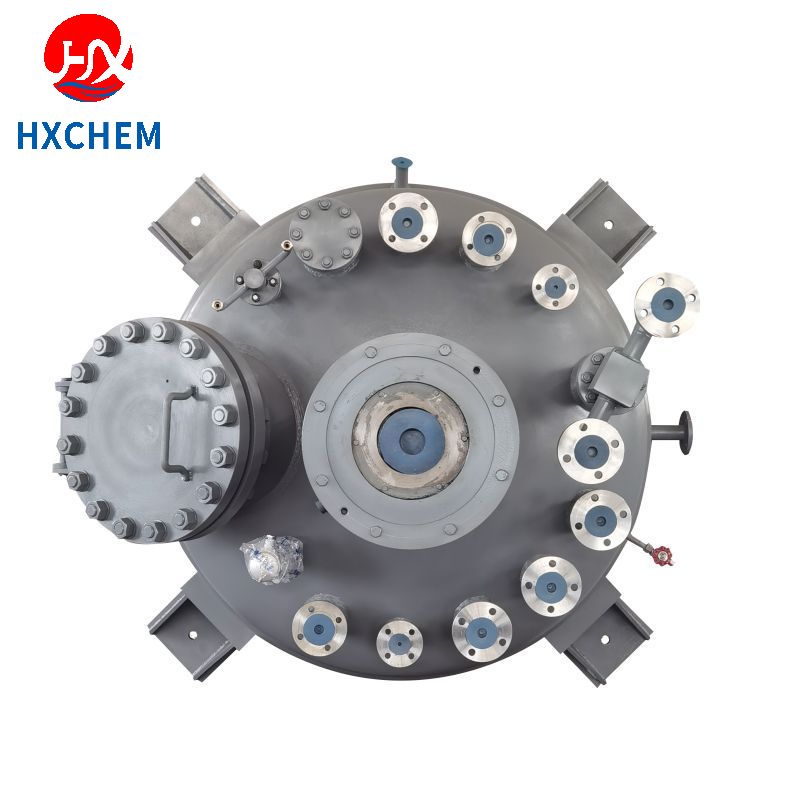

Nickel alloy pressure reactors

Introduction

Nickel-6 (>99.5% pure) is one of the pure nickel. It offers extensive advantages including outstanding resistance to various corrosive and caustic conditions, alkalis, and acids at the different magnitudes and temperature limits. Nickel-6 is resistant to reducing, oxidizing & neutral conditions and offers outstanding resistance to caustic alkalis in the high temperature. Nickel metal, almost silvery white, is a hard, ductile and ferromagnetic metallic element that is highly polished and resistant to corrosion. At room temperature, nickel forms a dense oxide film on the surface of humid air, which not only prevents further oxidation, but also resists corrosion from alkali and salt solutions. Nickel Alloy Reactor is mainly used in strong alkali and salt solution environments. Nickel Alloy Reactor is used in the chemical production of dyes and dye intermediates or other alkaline media.

Application: H acid;Alkali melting process;

Nickel-based alloy reactor | Nickel pressure reactor

Product Features

? Large scale production- maximum volume reach to 100m3

? Max pressure: 200 bar; Max temperature up to 300 ℃

? Material: Nickel-6(Ni6)

? When cladding plates be considered, including base material for strength and clad material for anti-corrosion. Reduce costs for you!

? Low to high torque magnetic couplings: static seal with no leakage.

? Accurate Impeller selected for the mixing mission and requires.

? Internal cooling coil, vent port, liquid/powder charging, dip tube, thermowell, safety rupture disc, pressure safety valve, flush bottom outlet, baffles, light & sight glass, handhole/manhole, etc.

Nozzles, manual / automated valves, fittings, control panel & accessories offered based on requirement.

? Lugs or floor stand leg support.

Technical Specifications

| Model | FCH 1000~100000 |

| Norminal volume | 1000L-100m3 |

| Material | Nickel |

| Working pressure | -1~200 bar |

| Working temp. | 0~300℃ |

| Motor power | 5.5kW-125kW |

| Stirring speed | 200~400rpm |

| Sealing method | Magnetic seal Mechanical seal |

| Stirrer | Porpeller;Paddle type; Anchor type;Turbine type Other as designed |

| Head type | Elliptical type Conical type Hemispherical type Flat type |

| Heating type | Oil electric heating Oil heating Steam heating |