Industrial short path evaporator

Short Path Evaporation is a specialized process for gently processing heat sensitive, high boiling products, utilizing an internal condenser and Wiped Film rotor technology. Heating area of industrial short path evaporator range from 1 m2 to 20m2, Industrial short path evaporator / wiped film evaporator for sale / wiped thin film evaporator / short path evaporator/ Short path wiped film evaporator/ Short path thin film evaporator

- HXCHEM

- China

- 30 days after payment

- 15 sets/month

Details

Industrial Short Path Evaporator

Introduction

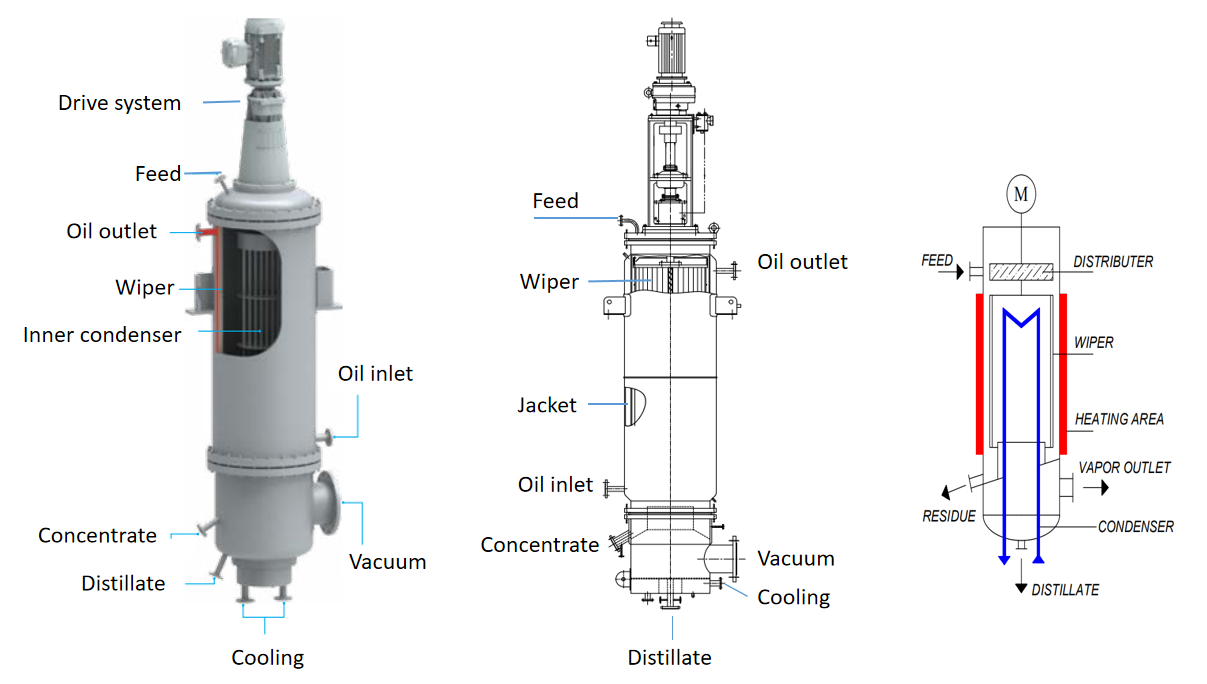

Short path evaporator (SPE)(Also called Molecular distillation) is a special type of thin film distillation technology, which combines thin film evaporator and condenser in a single apparatus. The vapour are condensed on the built-in condenser. The product path between the evaporation and condensation is extremely short, therefore, the pressure drop is low

The internal condenser of the Short Path Evaporator provides minimal pressure drop, permitting high vacuum operation. High vacuum operation is then combined with Wiped Film rotor technology, enabling short residence time, which allows processing of many heat sensitive and difficult to distill products. Short Path Evaporation is also called molecular distillation, and a Short Path Evaporator is sometimes known as an SPE.

Product Features

☆ Evaporation area: 1m2, 2m2,4m2, 6m2, 8m2,10m2,12m2, 14m2, 16m2, 20m2

☆ Temperature up to 350℃

☆ Material: Carbon steel; SS304, 316L, Duplex steel.

☆ Short path evaporation with minimal pressure loss, High working vacuum

☆ Different wiped film rotor are selected depending on the product properties.

☆ Double end mechanical seal / Magnetic seal optional.

Technical Specification

Type | Evap. area | Condenser area | Feeding rate | Inner diameter | Height |

m2 | m2 | kg/h | mm | mm | |

SPE-1 | 1 | 2.2 | 30~100 | 315 | ~2600 |

SPE-2 | 2 | 4.5 | 80~200 | 415 | ~4000 |

SPE-4 | 4 | 9 | 150~400 | 600 | ~5200 |

SPE-6 | 6 | 13 | 450~600 | 800 | ~5770 |

SPE-8 | 8 | 17.5 | 550~800 | 900 | ~6800 |

SPE-10 | 10 | 20 | 700~1000 | 1000 | ~7000 |

SPE-12 | 12 | 24 | 1200~2000 | 1200 | ~7200 |

SPE-20 | 20 | 30 | 1800~3000 | 1400 | ~10500 |

| Material | CS; SS304; SS316; Duplex steel; Titanium | ||||

| Heating type | Oil heating; Steam heating; Water heating | ||||

| Jacket type | Limpet coils jacket, Full jacket type | ||||

Vacuum Level (mbar) | Low to 0.001 mbar | ||||

Speed (rpm) | 50-400 | ||||

Working Temp. (℃) | Up to 350℃ | ||||

Larger sizes can be customized according to customer's requirements. | |||||

Note: Data in the table are standard specification. The specific size is based on the customer's demand.

Structure features

☆ Upgrade bottom residues & distillates collection stucture

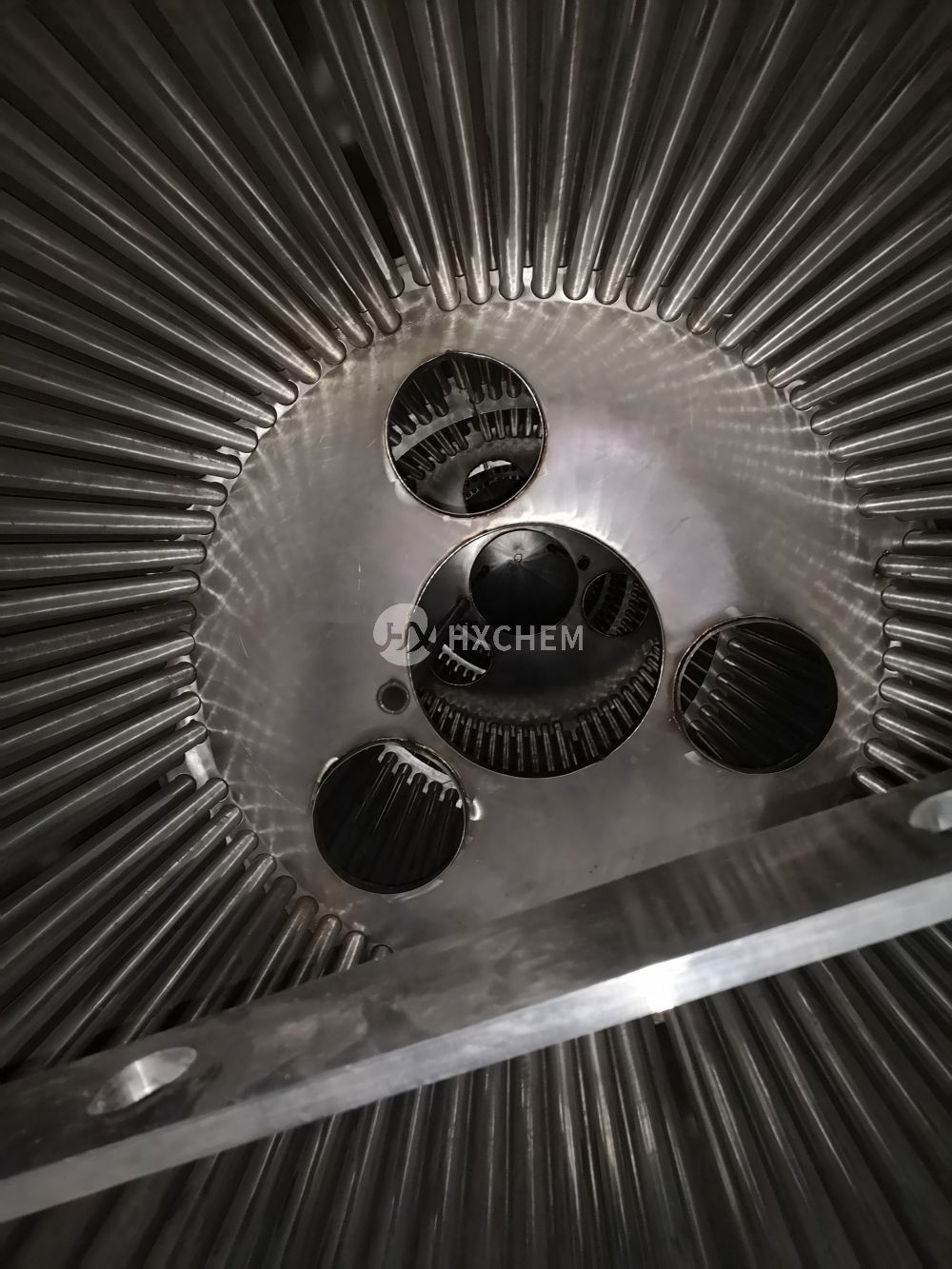

☆ Feeding device: Dis plate with sawtooth type.

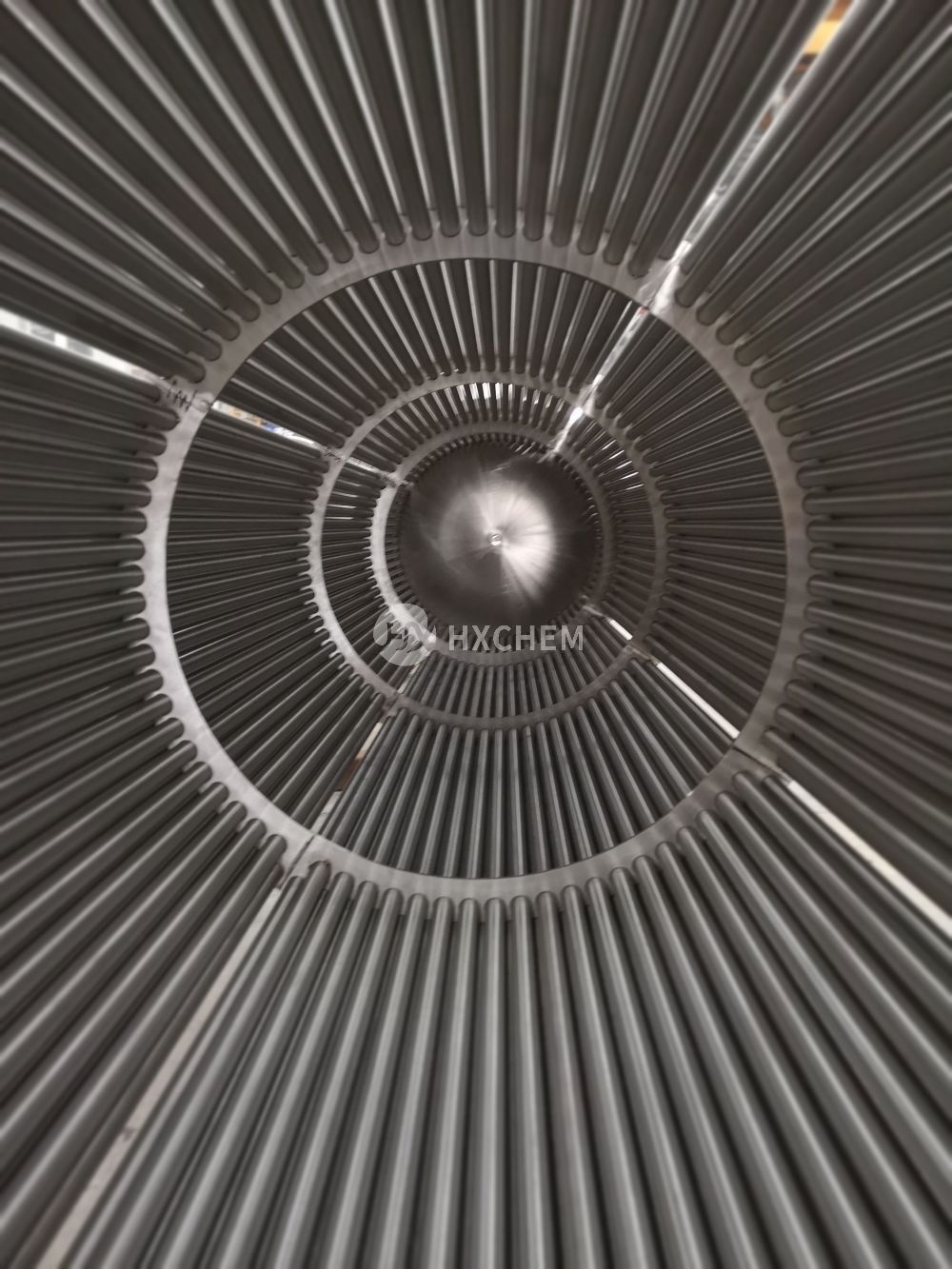

☆ Different wiper & sperator design inside.

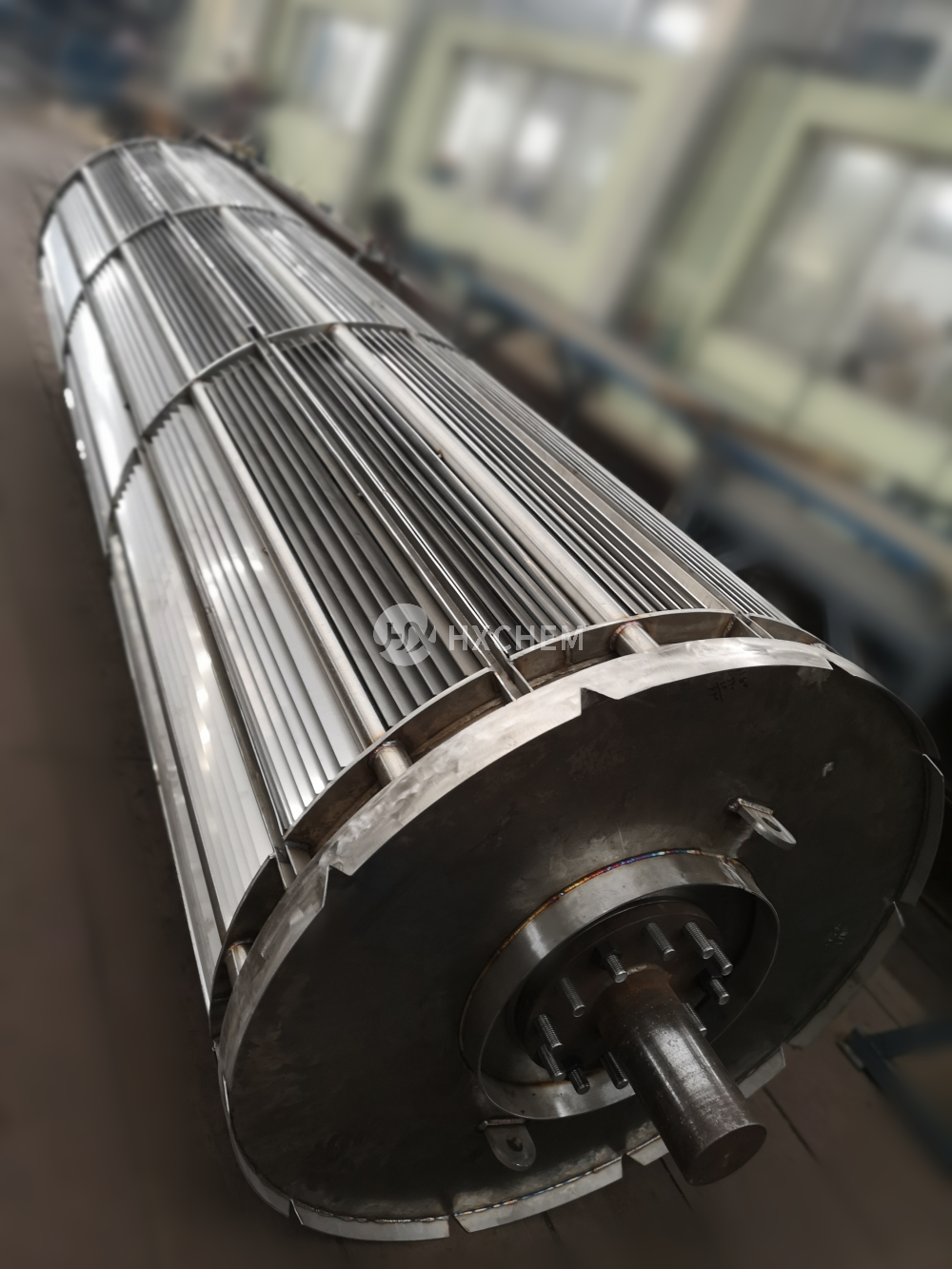

☆ Heating jacket: Limpet coils type or full jacket optional.

☆ Internal cooling tube: vertical tube or multi-tube type.

Product Details

Application

Short path evaporator is applied for separation of high boiling point, heat-sensitive and oxidizable materials.

Methanol recovery; Drying; Distillation of TDI, HDI and MDI (isocyanates); Final removal of toluene from epoxy resin; Concentration; Oleochemicals, Fatty Acids, Biodiesel; Drying of industrial sludge; Drying of preliminary and intermediate products from chemical industry; Drying of lubricants for forging industry; Polymers; Fine Chemicals;