Fixed clearance rigid scraping thin film evaporator

Fixed clearance rigid scraping thin film evaporator is suitable for the certain viscosity dry and solvent recovery, generally less than 50,000 cps. Fixed clearance rigid scraping thin film evaporator/ thin film evaporator / wiped film evaporator for sale / wiped thin film evaporator/ Fixed clearance thin film evaporator/ wiped fim evaproator(WFE)/ Thin film dryer

- HXCHEM

- China

- 70 days after payment

- 5sets/ month

Details

Fixed clearance rigid scraping thin film evaporator

Introduction

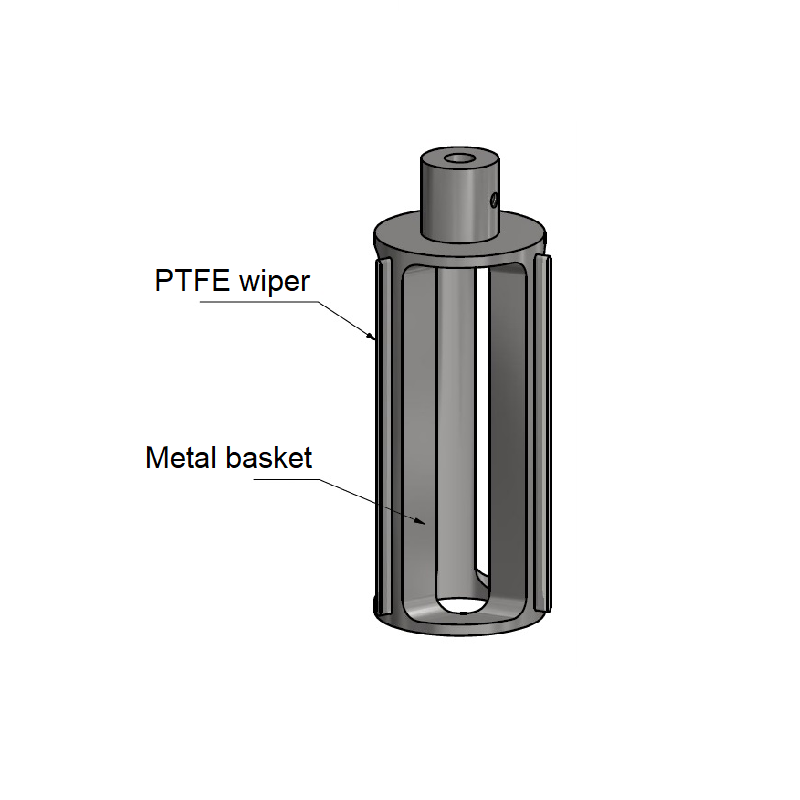

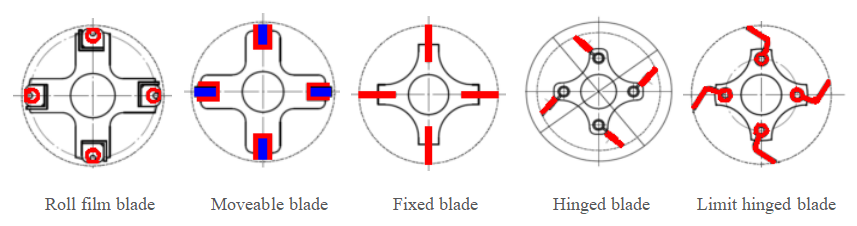

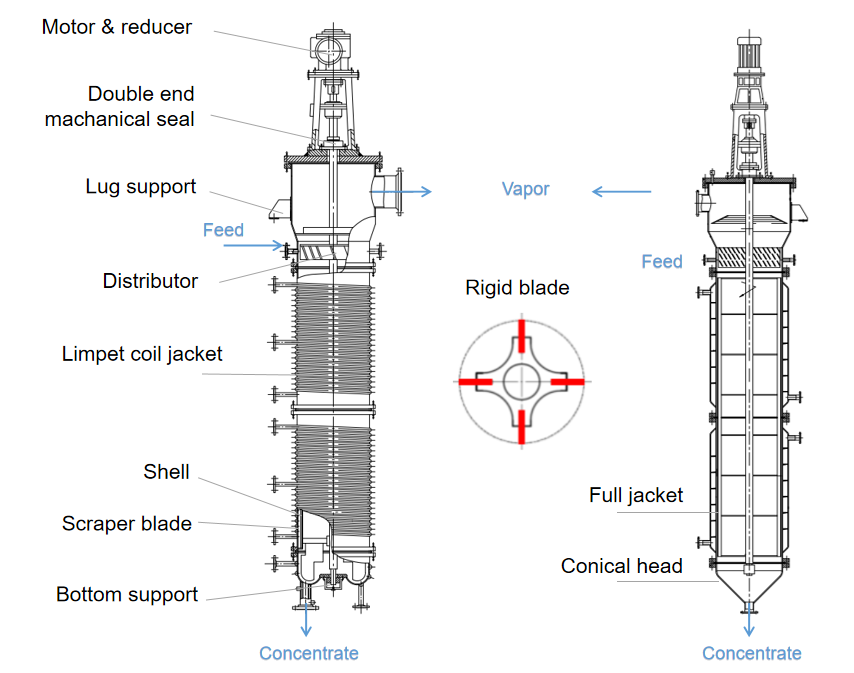

This series thin film evaporator(TFE), wiped film evaporator(WFE) equipped with the rigid fixed blade, which is suitable for the application of less viscosity dry and solvent recovery. The scraper length and heating surface of this series evaporator are the same height. According to the width of the blade and the size of the evaporator, the gap between blade and heating wall can be adjusted by 1-3mm(Fixed clearance evaporator). Since it does not contact with the heating surface, therefore, no self-cleaning and no abrasion to the heating surface. For some materials with high viscosity and crystalized product, spiral rigid scraper can be used. It is suitable for materials with certain viscosity. HXCHEM has several fixed scraper type optional to meet the requirements of different rotating speeds in high viscosity application.

Vertical fixed clearance rigid rotator is used for less viscous liquids, generally less than 50,000 cps. The vertical configuration provides reliable, efficient processing of viscous and fouling fluids. Units are available with either an internal or external bottom bearing.

Product Features

Evaporation area: 2m2, 4m2, 6m2, 8m2, 10m2, 12m2, 14m2, 16m2, 20m2

Temperature up to 350℃

Scrapped wiper:Customize based on client process and requirements

High evaporation rates;Short residence time and low evaporation temperature.

Double mechanical seal or Magnetic seal

The inner surface of the barrel is polished, with high smoothness.

High-performance distributor, not sticky to the wall.

Technical Specifications

Type | Evap. area | Feeding rate | Inner diameter | Height | Power |

(m2) | (kg/h) | (mm) | (mm) | (kW) | |

TFE-1 | 1 | 50~120 | 313 | ~3100 | 1.5-7.5 |

TFE-2 | 2 | 100~250 | 350 | ~4100 | 2.2- |

TFE-4 | 4 | 200~350 | 400 | ~5400 | 4- |

TFE-6 | 6 | 350~600 | 500 | ~6500 | 5.5- |

TFE-8 | 8 | 450~700 | 700 | ~7000 | 7.5- |

TFE-10 | 10 | 600~950 | 800 | ~7000 | 7.5- |

TFE-20 | 20 | 2000~3200 | 1200 | ~9500 | 15- |

Material | Carbon steel; SS304; SS316; Duplex steel; Titanium | ||||

Wiper type | Up to material viscosity and process | ||||

Heating type | Oil heating; Steam heating; Water heating | ||||

Jacket type | Limpet coil, Std. type jacket | ||||

Vacuum Level (mbar) | Low to 1 mbar | ||||

Speed (rpm) | 50-400 | ||||

Working Temp. (℃) | Up to 350C | ||||

Can be customized according to customer's requirements. Max. evap. area:50m2. | |||||

Note: Data in the table are standard specification. The specific size is based on the customer's demand.

Structure features

There are two types structure optional for your process!

Heating jacket: Limpet coil jacket, Full jacket optional.

Bottom discharge type: Elliptical type and conical type discharge.

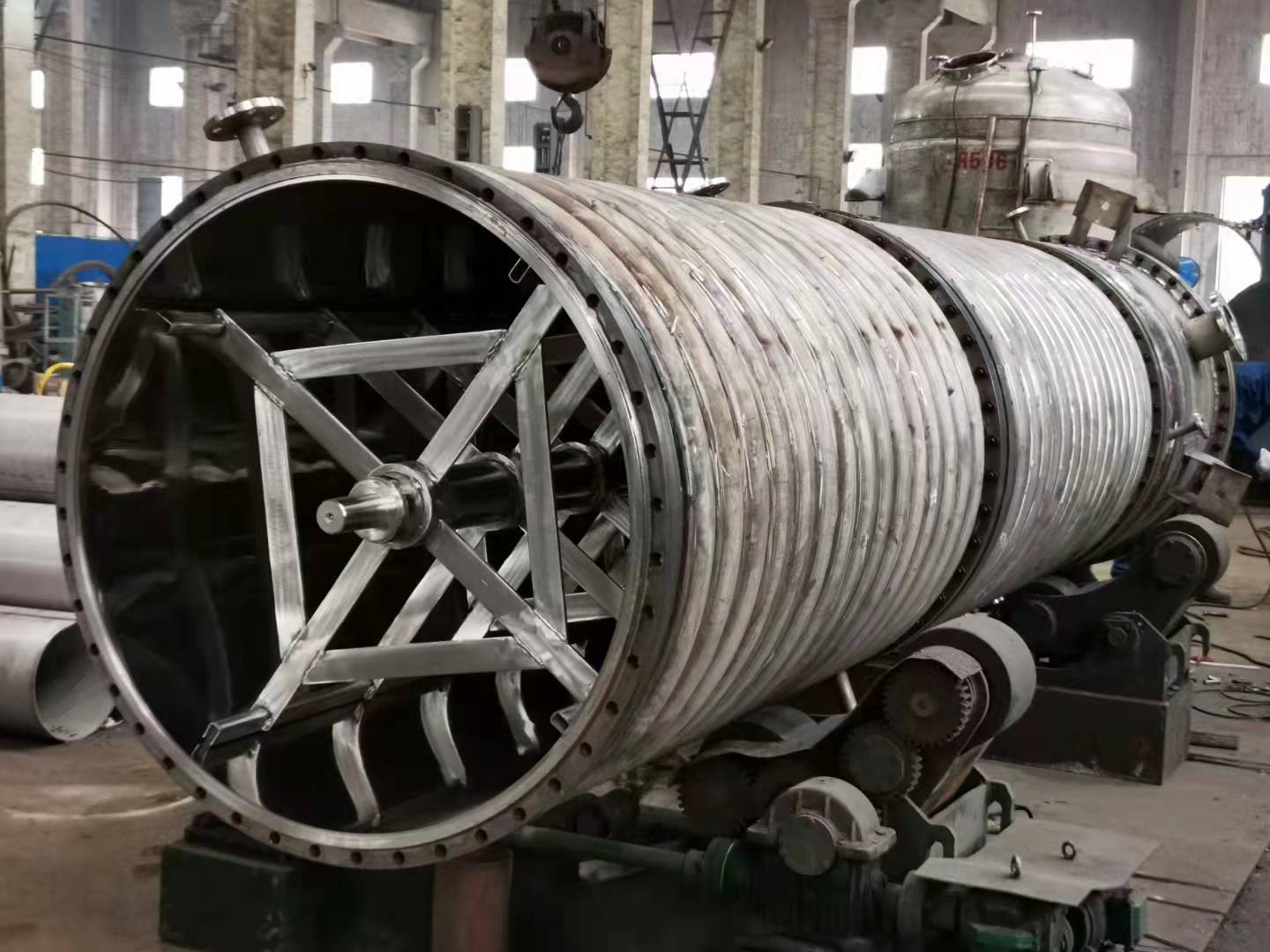

Product Delivery

Application

The fixed clearance rigid scraping thin film evaporator/ Thin film dryer/ thin film evaporator / wiped film evaporator for sale / wiped thin film evaporator/ Fixed clearance thin film evaporator/ wiped fim evaproator(WFE) is mainly used in the pre-treatment process of food and health products, also widely used in solvent removal and distillation separation in pharmaceutical, chemical industry and other industries.

Dryer, Concentration;Ethanol recovery;Solvent recovery;

Distillation, Separation, Concentration, Stripping, Deodorization/Deodorization, Degassing

Heat sensitive, viscous, fouling and foaming products

High-boiling, high-viscosity or crystallizing products

Continuous processing